HPP machine for the food industry

Is HPP machine safe?

HPP machine (High Pressure Pulse Processing) has many advantages in ensuring food safety and extending shelf life, and is recognized and supported by many food safety agencies.

HPP uses high water pressure to process food, which can effectively kill or reduce bacteria, parasites, yeast, mold and other microorganisms in food, thereby reducing the number of pathogenic microorganisms in food and reducing the risk of food poisoning caused by bacteria in food.

Compared with traditional heat treatment methods, HPP is a non-thermal treatment technology and therefore has less impact on the texture, taste and nutritional value of food. It retains nutrients, flavor and texture in food while extending its shelf life and providing a longer shelf life.

How long does HPP last?

about 30-45 days

For most foods, the shelf life after high pressure processing (HPP) is generally longer than that of unprocessed foods. Generally speaking, the shelf life of food treated with HPP is about 30-45 days.

During the HPP process, food is placed under high water pressure and microorganisms are inactivated or significantly reduced, thereby extending the shelf life of the food. According to the information you provided, the shelf life of juice after HPP treatment can usually be extended to 30-45 days, while the untreated raw juice can usually only be kept for 3-5 days.

It’s worth noting that shelf life also depends on other factors, such as the type of food, how it’s packaged, and storage conditions. Proper packaging and storage methods (such as refrigeration or freezing) can also further extend the shelf life of HPP-treated foods.

How much does HPP machine cost?

Cost of HPP (4.4–10.4 ¢/kg for a 420-l system) was also within the range of the cost estimated in this study. Mujica-Paz et al. (2011) estimated the cost for HPP (600 MPa for 3 min, 300-l vessel and 60 % of vessel filling ratio) of 15.7 ¢/kg for a 1,440 kg/h of production.

It is important to note that the cost of HPP can be affected by multiple factors, including the size, capabilities and efficiency of the equipment, as well as market conditions in the region. Therefore, actual HPP costs may vary.

Is HPP Machine FDA approved?

HPP technology is widely recognized in the food industry and is supported and recognized by multiple food safety agencies. These agencies include the World Health Organization (WHO), the U.S. Food and Drug Administration (FDA), the European Food Safety Authority (EFSA), etc., which provide guidance and supervision on the use and application of related technologies.Why is HPP better than thermal processing?

What are examples of high pressure processing foods?

High Pressure Processing (HPP) is widely used in various food types. Here are some examples of high pressure processed foods:

Juices and Smoothies: Juices such as apple juice, orange juice, grape juice and mixed fruit smoothies.

Purees, jams and jellies: apple puree, strawberry jam, blueberry jelly, etc.

Avocado Halves and Guacamole: Pressure-processed cut avocado slices and guacamole.

Shellfish: oysters, lobsters, crabs and other shellfish products.

Cured ham: Cured ham and other cured meat products.

Snack selection: vegetable slices, fruit plates, cheese cubes and other snacks.

Cooked meat: High-pressure processed cooked meat products, such as ham slices, turkey slices, etc.

Wet Salads and Dips: Wet salads and dips such as coleslaw and salsa.

These are just some examples of high-pressure processed foods. In fact, HPP technology can be applied to many more types of foods, including meat products, seafood, vegetables, nuts and grain products, etc. Through high-pressure processing, these foods can achieve a longer shelf life while maintaining their freshness, texture and nutritional value.

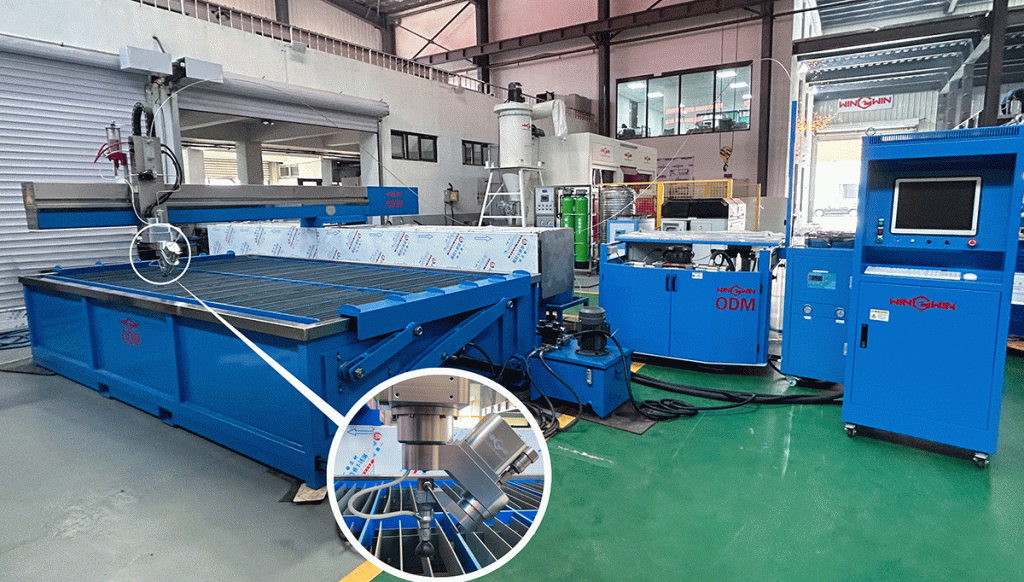

What are the basic components of HPP machine?

The basic components of the HPP system include the following key components:

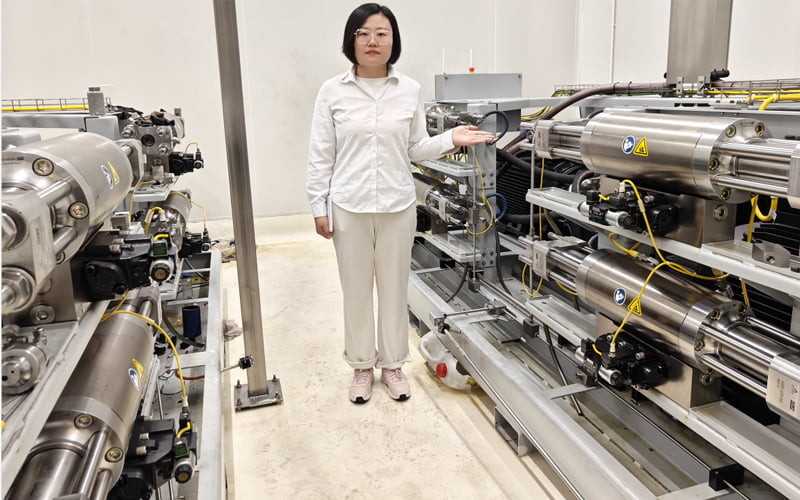

Pressure Vessel: A pressure vessel is the primary component that withstands high pressure and is usually made of strong materials such as stainless steel. It is strong and tight enough to contain the pressure exerted during high-pressure processing.

Pressure transmission fluid: HPP systems use a liquid medium (such as water or food grade liquid) as the pressure transmission medium to transmit pressure into the pressure vessel. These liquid media circulate in the system and provide the required pressure through 100,000psi high-pressure water jet pumps .

| AT01381 | Repair Kit HPPA-KM-5803-1 | AT01230 | HPE Stem |

| HPPA-KM-5803-1-2 | tool | AT01232 | HPE Packing assembly |

| HPPA-KM-5813 | Hydraulic Cartridge 05130091 | AT01231 | HPE Packing Follower |

AT01288 | HPE TUBE,High pressure bent.38 | AT01233 | HPE Seat |

| AT04196 | HPE Tube,high pressure ,long intensifier | 040015-1 | HPE Carrier Seal |

| AT03910 | HPE High Pressure tube 2 Closure short | HPPA-KM-5803-1, 040015-1 | HPE Repair Kit |

AT02682 | HPE High Pressure tube , Closure Long | HPPA-KM-5803-1-2 | Repair Kit Tool |

| AT07892 | HPE Discharge Block only | 012763-1 | HPE Bleed Down Valve Actuator |

| 011742-1 | HPE Bleed down body | 013561-1 | HPE 350L/100L Blowdown Valve Repair Kit |

| 014885-1 | HPE Intensifier Check Valve Outlet Side Main | 014884-1 | HPE Intensifier Check Valve Inlet Replacement Kit |

Material handling pressurization system: The material handling pressurization system is used to enter the food to be processed into the pressure container and remove the processed food from the container after the processing process is completed. It usually includes equipment such as conveyor belts, conveyors, and robotic arms used to move and position food.

Heating or cooling components: Some HPP systems may be equipped with heating or cooling components to control the temperature during processing. The heating component can provide heating medium to bring the food to the required temperature during high-pressure processing. The cooling component can quickly cool the food through the cooling medium to maintain the freshness and quality of the food after processing.

Food safety without heat or preservatives

Welcome to the foodie nation, where almost everyone’s a picky eater. A 2014 study found that 72 percent of consumers buy foods based on healthfulness. That number will continue to rise with the popularity of HPP.

By processing foods at extremely high water pressure (up to 6,000 bar / 87,000 psi – more than the deepest ocean), Avure HPP machines neutralize listeria, salmonella, E. coli and other deadly bacteria.

Unlike thermal, chemical and other high-heat treatments, HPP runs cold. It doesn’t alter food taste, texture or quality, or require loads of chemicals to stay “fresh.” Even better, it can extend shelf life up to two or three times longer than traditional preservation methods.

You’ll find foods processed by HPP systems in every corner of the world. From guacamole to organic fruit juice, BBQ brisket and tabouli, Avure’s HPP makes them better.