PROJECT CASE

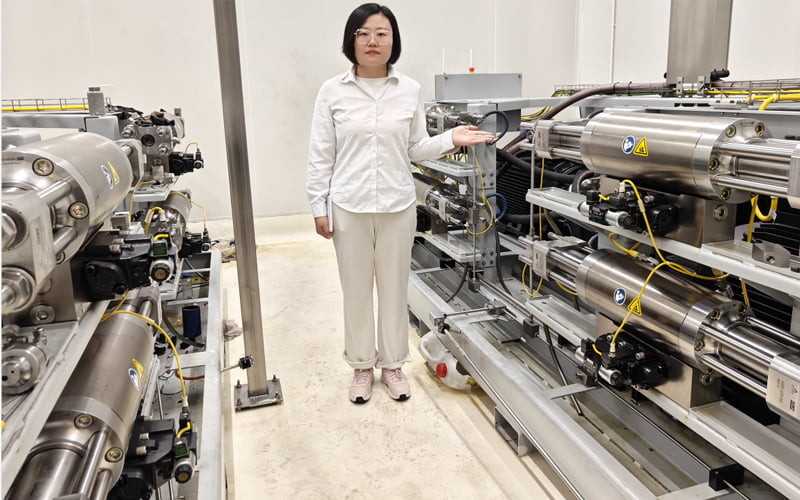

WATERJET PUMP

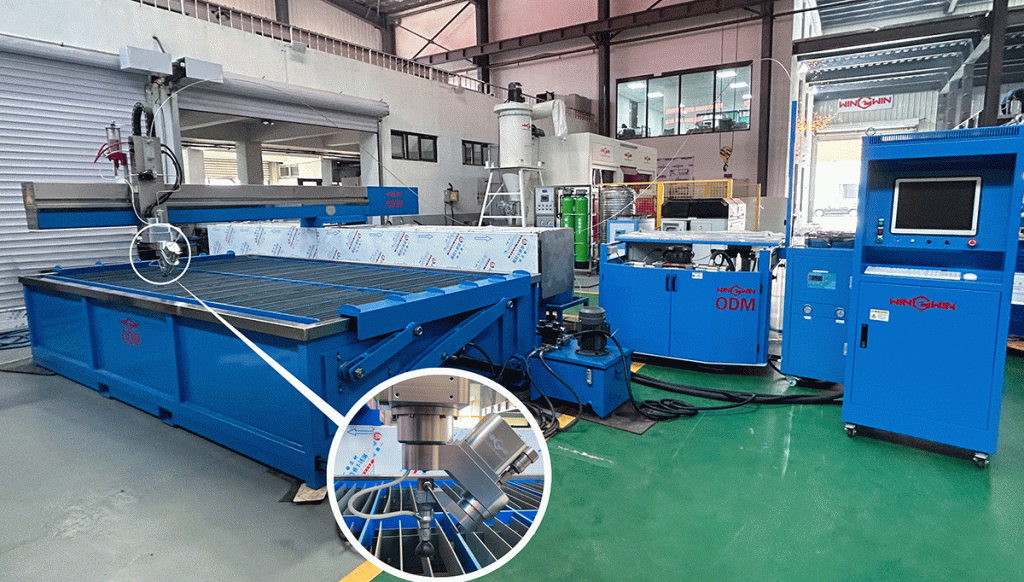

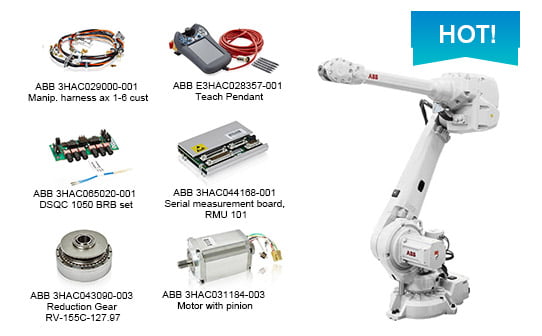

ROBOT&WATERJET PARTS

Turkey IDEF International Defense Exhibition

WINWIN Waterjet – The Defense Industry Cutting Solution WINWIN intensifier pump technology and abrasive cutting heads have been extensively used

WINWIN Provides Technology Upgrading for the King of Steel and Iron

For metals like titanium, steel, brass, or aluminum, waterjet is the most versatile cutting method available. Waterjet tables can be

International Consortium injects capital into WINWIN Waterjet

The origin of water jet cutting technology The origins of water jet technology can be traced back to the mid-20th century. Water jet cutting is

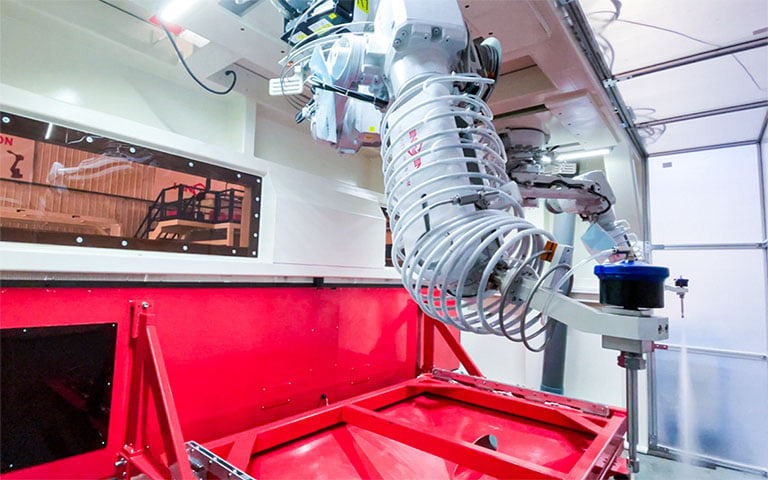

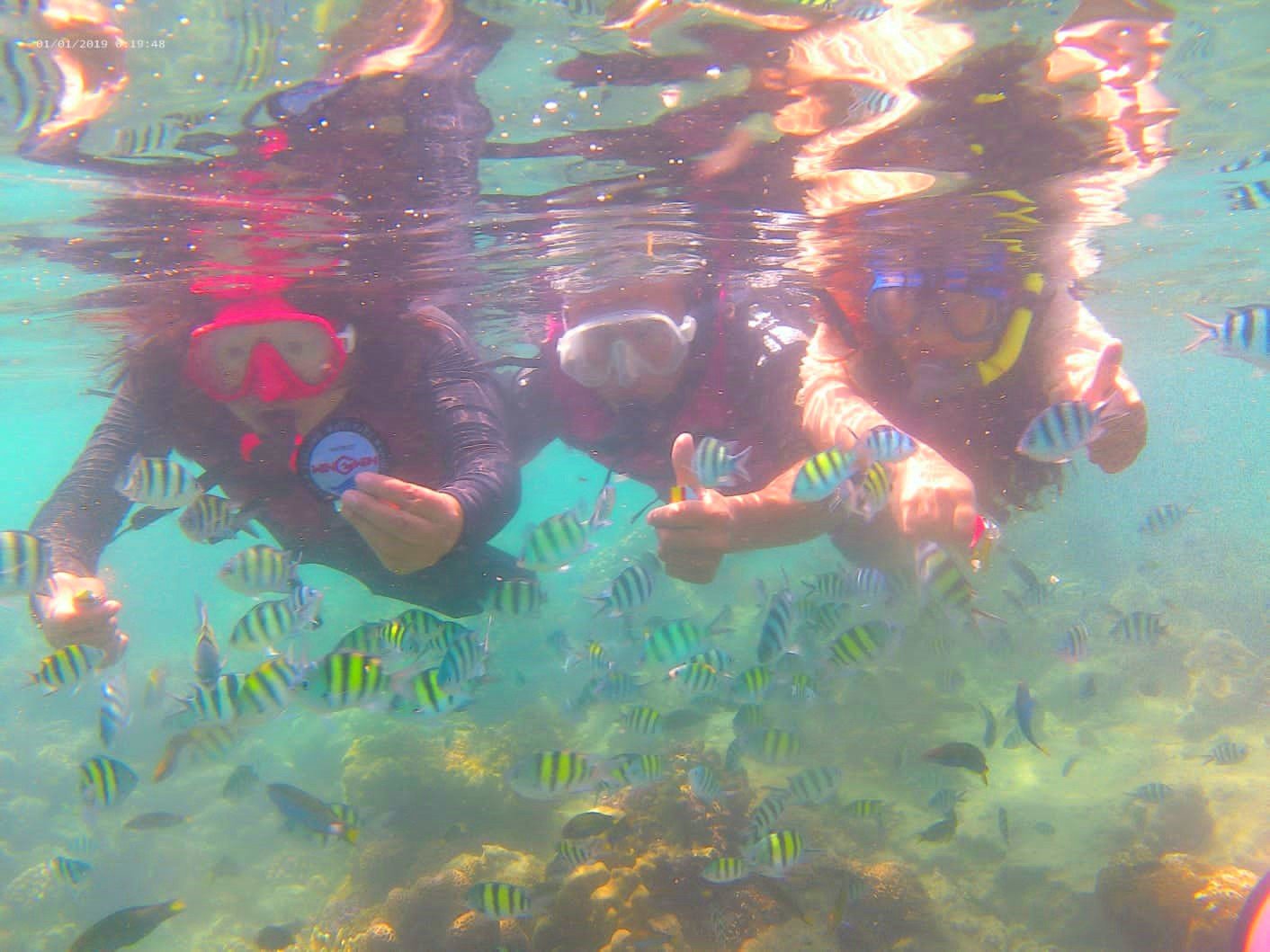

WINWIN technicians are invited to snorkel after the Marine industry Customer Project is installed

Waterjet Cutting for Marine Industry Water jet technology has broad application prospects in the Marine industry. It offers boat builders an