044136-1 F-LOW Waterjet Cutting Head

Description

044136-1 F-LOW Waterjet Cutting Head

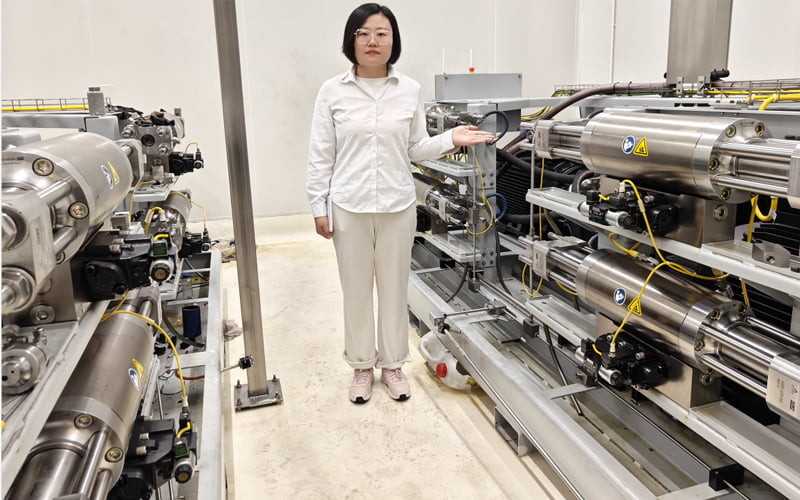

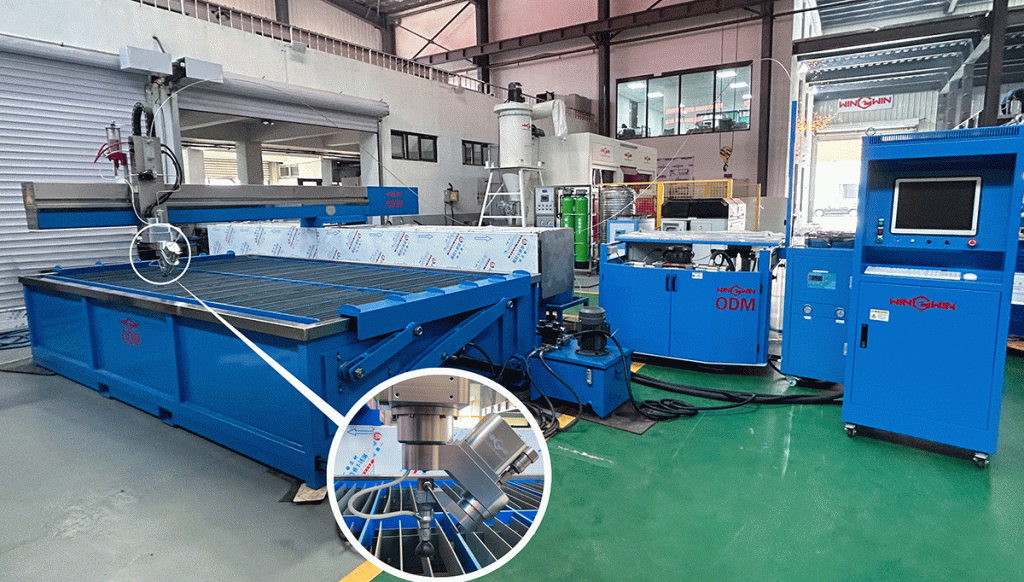

044136-1 F-LOW Waterjet Cutting Head Assembly produced by WINWIN Waterjet is of high quality. FLOW Waterjet is a well-known manufacturer of waterjet cutting machines and related components. WINWIN Waterjet is also a world-renowned supplier of water jet robot cutting projects, abrasive water jet cutting machines, and 100,000psi ultra-high pressure pumps. waterjet cutting head is a key component of a waterjet cutting system. It is responsible for delivering a high-pressure stream of water mixed with abrasive particles to cut through various materials.

| Parts Number | Parts Name |

| 014559-1 | ACTUATOR ASSEMBLY |

| 014554-1 | VALVE BODY |

| 014988-1 | ON/OFF REPAIR KIT |

| 710876-1 | VALVE NUT |

| 044347-1 | GLAND NUT |

| 044136-1 | CUTTING HEAD ASSEMBLY |

| 711933-1 | DISK BLAST |

| 040411-1 | NOZZLE SPLASH GUARD |

| 711589-1 | NOZZLE NUT |

| MIXING TUBE | |

| 009519-X | ORIFICE |

| 041138-1 | MIXING CHAMBER |

| 041373-1 | NOZZLE BODY |

| 014660-1 | ON/OFF VALVE |

How can I determine whether my application will require abrasive?

Abrasives are used in waterjet cutting machines when the application involves cutting hard materials such as metals, ceramics, or stone. The decision to use abrasives depends on the material being cut, the desired cut quality, and other factors. Here’s when a waterjet cutting machine typically needs abrasives:

- Cutting Hard Materials:Waterjet cutting without abrasives is primarily used for softer materials like rubber, foam, or some plastics. When you need to cut hard materials, especially metals, abrasives become essential. The abrasive particles in the waterjet enhance the cutting power and allow it to erode through the hard material effectively.

- Thick Materials:When cutting materials with substantial thickness, abrasives are often required. Thicker materials can resist the waterjet’s erosion action, so adding abrasive particles increases the cutting efficiency.

- Precision and Edge Quality:Abrasives help improve the precision and edge quality of the cut. They allow for cleaner, smoother edges, reducing the need for additional finishing or machining.

- High-Speed Cutting: Abrasive waterjets are suitable for high-speed cutting of hard materials. The abrasive particles assist in breaking down the material quickly, which can be beneficial for large-scale production.

- Complex Shapes:Waterjet cutting with abrasives can handle intricate designs and complex shapes more effectively, as it provides greater control over the cutting process.

- Material Preservation:In some cases, using abrasives can minimize the amount of material removed during cutting, which is important for applications where material preservation is a concern.

- Heat-Sensitive Materials: When cutting heat-sensitive materials like certain plastics or composites, abrasive waterjet cutting is preferred because it generates minimal heat.

Efficiency: For industrial applications that require efficient material cutting and processing, abrasive waterjet cutting is a practical choice. It minimizes cutting time and maximizes productivity.

It’s important to note that the decision to use abrasives should be based on the specific requirements of the cutting task. Waterjet machines can typically be configured to operate with or without abrasives, allowing for flexibility in adapting to different materials and project goals. The choice of abrasive type, size, and concentration can also be customized based on the material being cut and the desired cut quality.

If you are interested in 044136-1 F-LOW Waterjet Cutting Head,you can contact us for price list.

Reviews

There are no reviews yet.