Is waterjet cutting or laser cutting cheaper?

The cost comparison between waterjet cutting and laser cutting can vary depending on various factors, including the specific application, material being cut, project scale, and regional factors.

Generally, laser cutting tends to be more cost-effective than waterjet cutting for certain materials and applications, while waterjet cutting may be more cost-effective for others. Here are some considerations for each method:

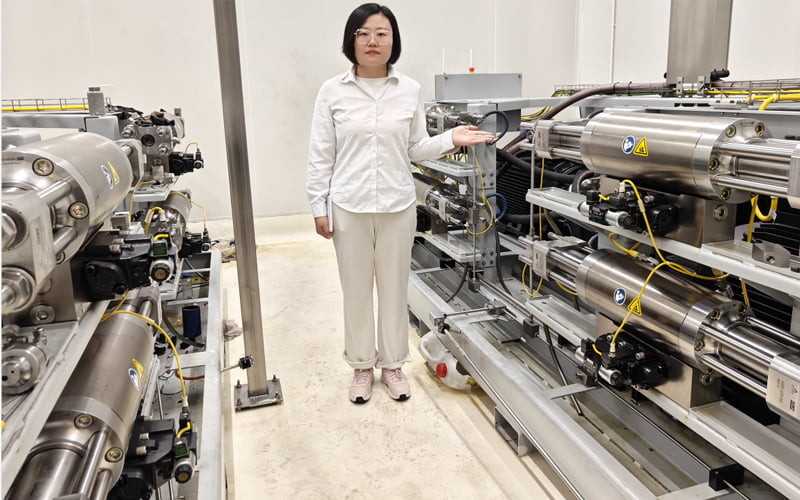

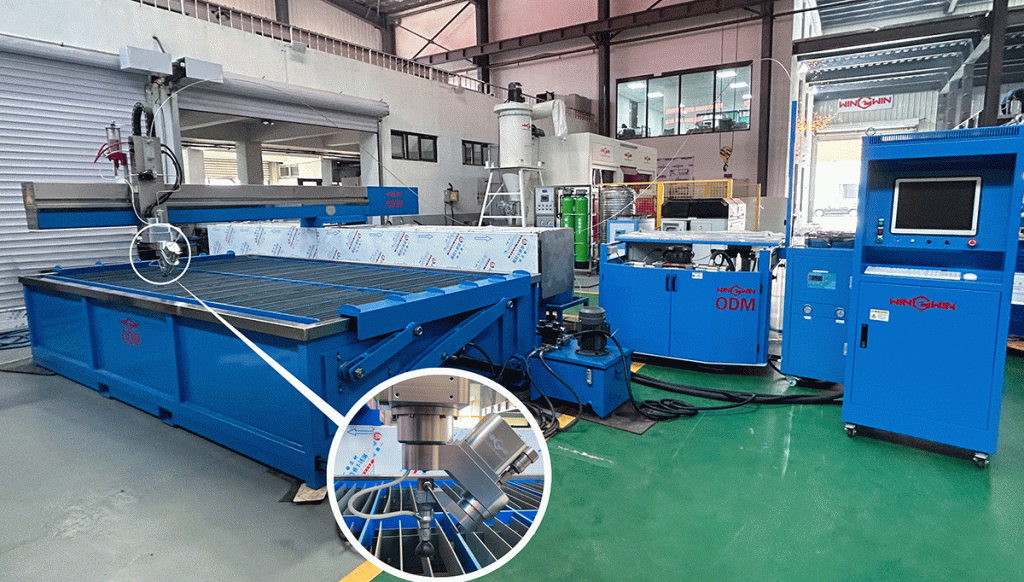

Waterjet Cutting

Waterjet cutting is typically more effective for thicker materials, such as metals over 1 inch thick, stone, and composites. It can cut through these materials without heat-affected zones or distortion.

Waterjet cutting does not require the use of expensive gases or laser optics, which can contribute to cost savings.

The operating costs of waterjet cutting, including electricity, water, and abrasive consumption, should also be considered

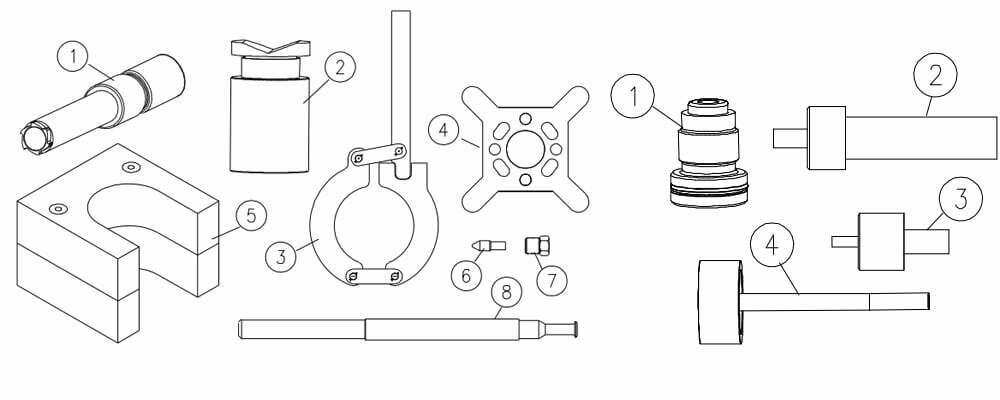

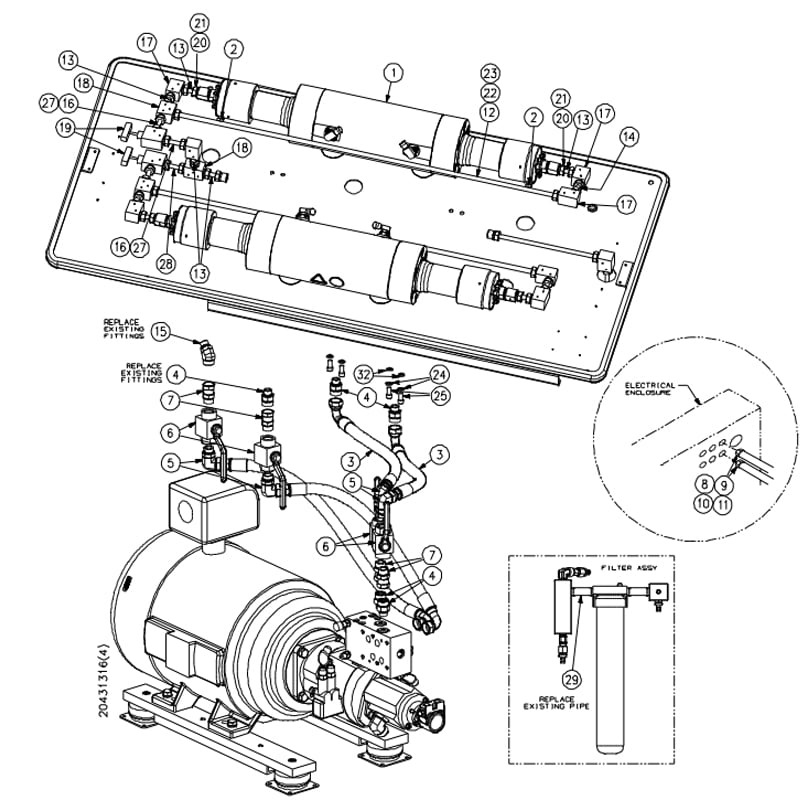

Maintenance Tools and Lubricants

| 20477460 | Plunger Removal Tool, .88 Plunger | 20484961 | Vee Block Cradle |

| 20477469 | Plunger Removal Tool, 1.13 Plunger | 05066139 | Cylinder Wrench |

| 10148674 | HP Seal Installation Tool, .88 Plunger | 80079239 | End Cap Wrench, HSEC, 6x/8x |

| 05146618 | HP Seal Installation Tool, 1.13 Plunger | 80078330 | HP Seal Removal Tool Stand |

| 10078129 | HP Gland, .38 | 10079523 | HP Plug, .38 |

| 10078608 | HP Gland, .56 | 10078772 | HP Plug, .56 |

| 20470475 | Seal Tool Kit, Pneumatic Control Valves | 20470417 | Seal Installation Tool |

| 05067350 | Seal Positioning Tool, NO/NC Valves, 2-Port Dump Valve | 49833114 | Seal Positioning Tool, Quick Release Valve, 3-Port Dump Valve |

| 20470413 | Seal Push Tool | 10084440 | Pure Goop Thread Lubricant |

| 10087385 | FML-2 Grease, 14.5 oz | 49832199 | JL-M Thread Lubricant, 16 oz. |

| 80082191 | JL-M Thread Lubricant, 15 ML | 20487868 | Threadlocker Adhesive |

| 20494983 | Threadlocker Primer | 10184802 | 10184802 |

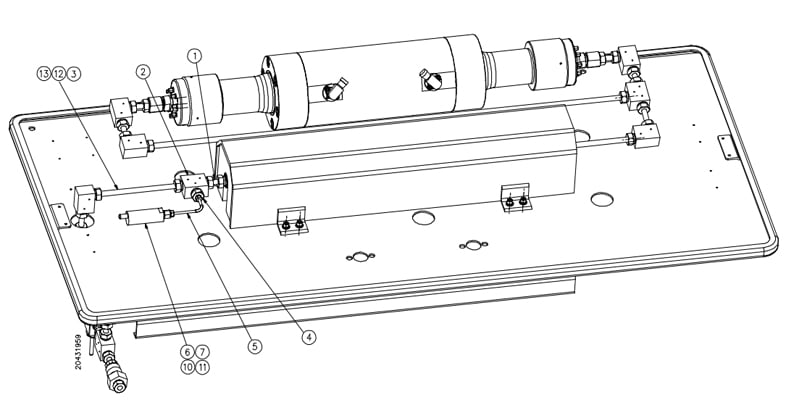

High Pressure Transducer

| 10069326 | HP Tube, .56 x 4.0 | 10176410 | Wire, #16, Blue |

| 10079465 | Tee, HP, .56 | 10185395 | Connector, Crimp Ferrule |

| 20412627 | HP Tube, .56 x 11.50 | 10078459 | HP Gland, .25 |

| 10079580 | Bushing, HP, .56 x .25 | 10078426 | HP Collar, .25 |

| 05071782 | HP Tube, Bent, .25 | 05086905 | Flexible Conduit, .63 |

| 49838478 | Pressure Transducer | 05131347 | Ferrule, .50 |

| 10067205 | Cable Connector, .50 | 20431959 | High Pressure Transducer |

Redundant Kit

| 72122493 | Intensifier Topworks | 10078525 | Elbow, HP, .56 x .56 |

| 05111406 | Adapter | 10079465 | Tee, HP, .56 |

| 80079536 | Hydraulic Hose Assembly | 10079275 | 2-Way Valve |

| 80079684 | Adapter, FSOR/ORB | 10078608 | HP Gland, .56 |

| 80079817 | Adapter, FSOR/ORB | 10079119 | HP Collar, .56 |

| 80079551 | Ball Valve, 2-Way | 05086905 | Conduit, .63 |

| 80079692 | Adapter, FSOR/ORB | 05131347 | Ferrule, .50 Hose |

| 20417552 | Connector Plug | 95413696 | Lock Washer, .50 |

| 10067205 | Connector Cable, .50 | 95383790 | Socket Head Screw |

| 10083012 | Lock Nut, .50 | 20417180 | SST Tubing |

| 10082857 | Gasket Assembly | 05074661 | HP Tube, .56 x 4.59 |

| 05145271 | HP Tube, .56 x 55.19 | 20413856 | Pipe Nipple, .75 x 9.0 |

| 10069326 | HP Tube, .56 x 4.0 | 20451641 | Latch Pin |

| 05145297 | HP Tube, .56 x 4.18 | 20421272 | Hose, Push-On, .50 |

| 80079809 | Adapter, FSOR/ORB, 1.0 x .75 | 49898729 | Flat Washer, M12 |

| 05112057 | HP Tube, .56 x 4.97 |

| 05108832 | Hand Coning Tool Assembly, .25 | 05109897 | Power Coning Tool Assembly, .25 |

| 05108857 | Hand Coning Tool Assembly, .38 | 05109889 | Power Coning Tool Assembly, .38 |

| 05108840 | Hand Coning Tool Assembly, .56 | 05109871 | Power Coning Tool Assembly, .56 |

| 05108808 | Blade, .25 | 05108972 | Collet, .25 |

| 05108824 | Blade, .38 | 05108964 | Collet, .38 |

| 05108816 | Blade, .56 | 20439964 | Collet, .56 |

| 05109814 | Retainer, .25 | 05109830 | Retainer, .56 |

| 05109822 | Retainer,.38 | 05120472 | Cone and Thread Lubricant, 4 oz |

Laser Cutting

Laser cutting is generally faster than waterjet cutting, making it more cost-effective for thin to medium-thickness materials, such as metals up to 1 inch thick and various non-metal materials.

Laser cutting is highly precise and can achieve intricate cuts, allowing for efficient material utilization and minimizing waste.

Laser cutting typically requires less maintenance and has lower operating costs compared to waterjet cutting.

However, laser cutting can generate heat-affected zones and may not be suitable for certain heat-sensitive materials or those prone to melting or warping.

| 05108865 | Hand Threading Tool Assembly, .25 | 05108899 | 1/4-20 Threading Die |

| 05108873 | Hand Threading Tool Assembly, .38 | 05108915 | 3/8-16 Threading Die |

| 05108881 | Hand Threading Tool Assembly, .56 | 10078301 | 9/16-18 Threading Die |

| 05122742 | Power Threading Tool Assembly, .25 | 05108741 | Retainer, .25 |

| 05120258 | Power Threading Tool Assembly, .38 | 05108758 | Retainer, .38 |

| 05122759 | Power Threading Tool Assembly .56 | 05108766 | Retainer, .56 |

| 05108782 | Tube Vise, .25 | 20437825 | Tube Vise, .75 |

| 05108790 | Tube Vise, .38 | 20440071 | Tube Vise, 1.0 |

| 05108774 | Tube Vise, .56 |

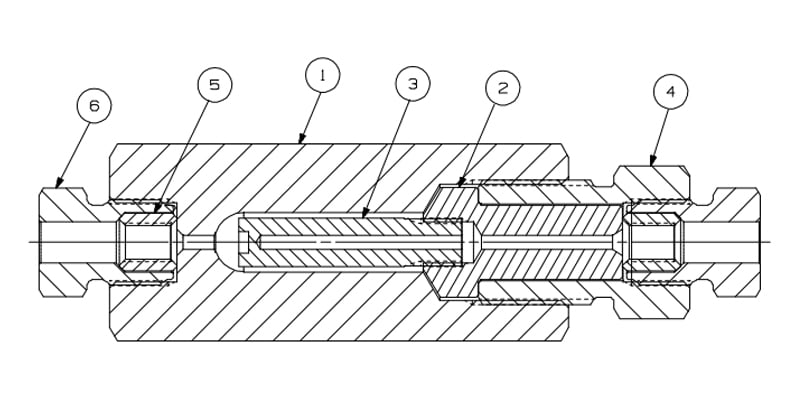

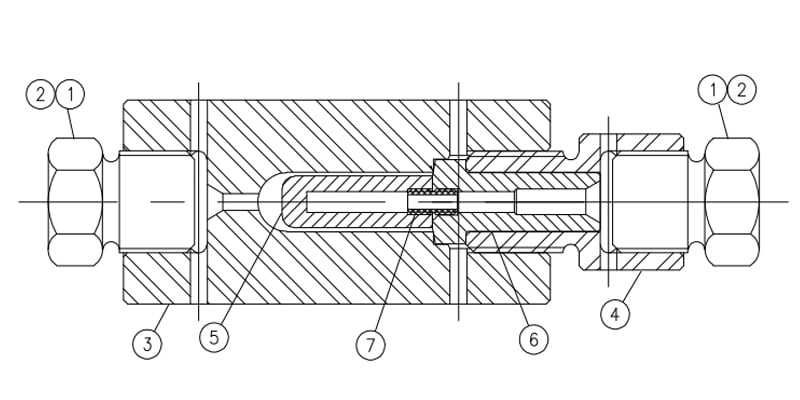

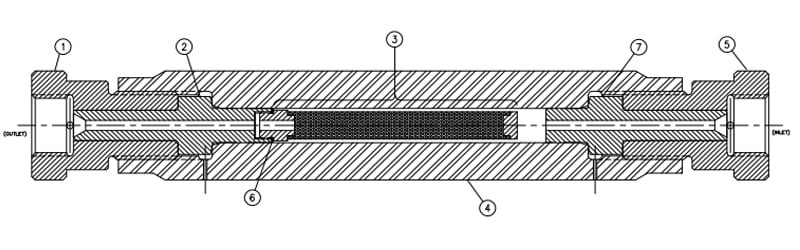

05114137 Inline Water Filter, .25

| 05114129 | Filter Body | 05114145 | Adapter Gland |

| 05114152 | Retainer, Filter Element | 10078426 | HP Collar |

| 05110531 | Filter Element | 10078459 | HP Gland |

CJ200988 Inline Water Filter, .38

| 10078715 | HP Collar | SKJA266 | Filter Element |

| 10078129 | HP Gland | SKJA286 | SKJA286 |

| CJ300988 | Filter Body | SKJA287 | Bayonet Nipple |

| CJ400988 | Adapter Gland |

BF103473 Inline Water Filter, .56

| AF413972 | HP Gland, Outlet | AF913972 | HP Gland, Inlet |

| AF303473 | Seal Head, Outlet | 10074599 | O-Ring, .38 x .50 x .06 |

| AF503473 | Filter Element | AF403473 | Seal Head, Inlet |

| BF203473 | Filter Body |

Ultimately, the cost-effectiveness of waterjet cutting versus laser cutting depends on

specific requirements , material to be cut, and the desired outcome.

It is advisable to consult with a professional cutting service provider to evaluate the most suitable and cost-effective method for your specific needs.

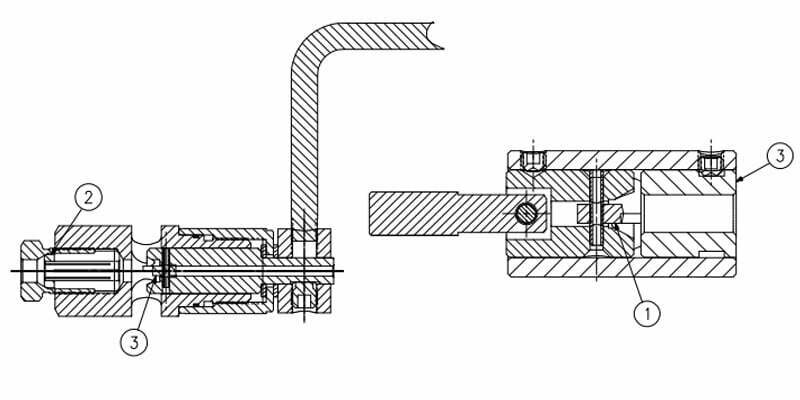

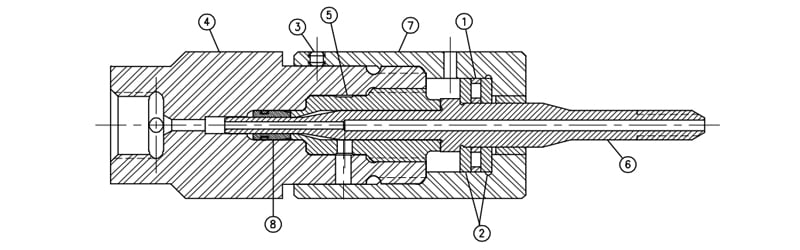

CJ211388 HP Swivel Joint, Straight, .25, M/F

| 10084713 | Thrust Needle Bearing | 10094647 | Thrust Washer |

| 10103505 | Setscrew, 6-32 x 1/8 | CJ311388 | Swivel Body |

| CJ401288 | Swivel Bushing | CJ501288 | Spindle, .25 |

| BJ701288 | Cap Assembly | BJ201388 | Seal Assembly |

| BJ701288 | Cap Assembly | CJ801288 | Cap, .25/.38, M/F |

| 10144442 | Swivel Bushing |

CJ218088 HP Swivel Joint, Straight, .25, F/F

| 10084713 | Thrust Needle Bearing | CJ418088 | Cap, .25 |

| 10094647 | Thrust Washer | CJ311388 | Swivel Body |

| 10103505 | Setscrew, 6-32 x 1/8 | CJ401288 | Swivel Bushing |

| 10154680 | Clamp Collar | BJ201388 | Seal Assembly |

| CJ318088 | Spindle, .56 |

Are there any other factors I should consider when deciding between waterjet cutting and laser cutting?

Material Compatibility

Both waterjet cutting and laser cutting have different material compatibility. Waterjet cutting can work with a wide range of materials, including metals, stone, glass, composites, and more. Laser cutting is suitable for various materials, such as metals, plastics, wood, acrylics, and some fabrics. Consider the specific material you need to cut and ensure that the chosen method is compatible.

Cutting Precision

Laser cutting generally provides higher precision and accuracy, especially for intricate designs and fine details. If your project requires precise cuts, intricate shapes, or tight tolerances, laser cutting may be the preferred choice.

10134708 HP Swivel Joint, Straight, .38, M/F

| 10084713 | Thrust Needle Bearing | 10094647 | Thrust Washer |

| 10103505 | Setscrew, 6-32 x 1/8 | 10134716 | Swivel Body |

| CJ401288 | Swivel Bushing | 49899602 | Spindle, .38 |

| BJ701288 | Cap Assembly | BJ201388 | Seal Assembly |

| 10078913 | HP Gland, Anti-Vibration | 10078715 | HP Collar |

CJ201288 HP Swivel Joint, 90D, .25, M/F

| 10084713 | Thrust Needle Bearing | CJ401288 | Swivel Bushing |

| 10094647 | Thrust Washer | CJ501288 | Spindle, .25 |

| 10103505 | Setscrew, 6-32 x 1/8 | BJ701288 | Cap Assembly |

| DJ301288 | Swivel Body | BJ201388 | Seal Assembly |

Cutting Thickness

Waterjet cutting is typically better suited for thicker materials, while laser cutting is more efficient for thinner materials. Consider the thickness of the material you need to cut and choose the method that aligns with your requirements.

Heat-Affected Zones

Laser cutting generates heat, which can result in heat-affected zones (HAZ) in the material being cut. If heat distortion or thermal damage is a concern for your project, waterjet cutting may be a better option.

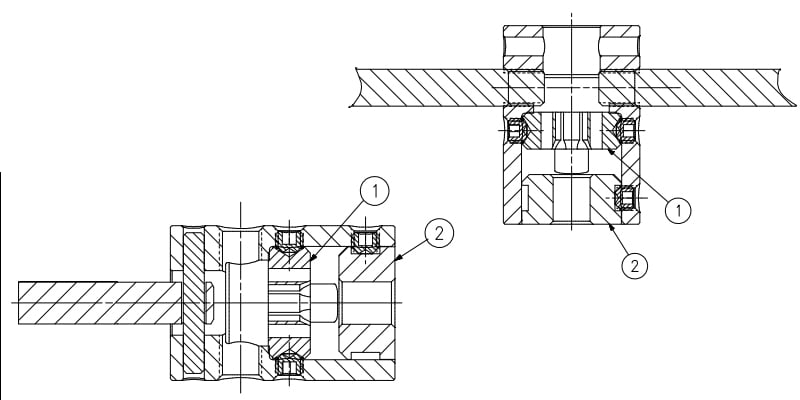

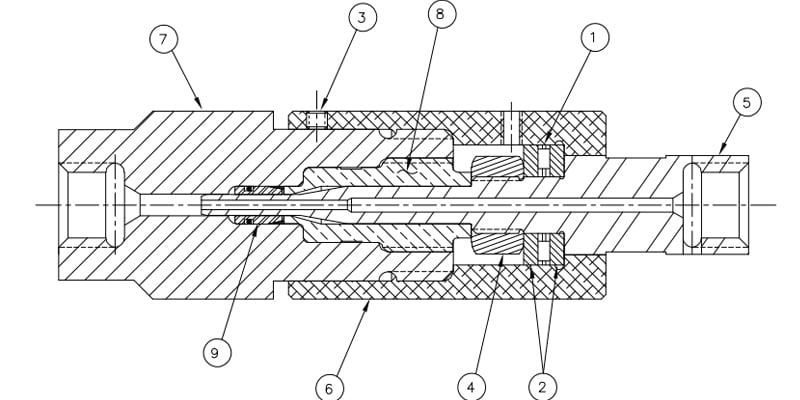

CJ218188 HP Swivel Joint, 90D, .25, F/F

| 10084713 | Thrust Needle Bearing | CJ418088 / 91959643 | Cap, .25 |

| 10094647 | Thrust Washer | DJ301288 / 91959635 | Swivel Body |

| 10103505 | Setscrew, 6-32 x 1/8 | CJ401288 / 91959627 | Swivel Bushing |

| 10154680 | Clamp Collar | BJ201388 / 91959650 | Seal Assembly |

| CJ318088 / 91960021 | Spindle, .56 |

10134682 HP Swivel Joint, 90D, .38, M/F

| 10084713 | Thrust Needle Bearing | 49899602 | Spindle, .38 |

| 10094647 | Thrust Washer | BJ701288 | Cap Assembly |

| 10103505 | Setscrew, 6-32 x 1/8 | BJ201388 | Seal Assembly |

| 10134690 | Swivel Body | 10078913 | HP Gland, Anti-Vibration |

| CJ401288 | Swivel Bushing | 10078715 | HP Collar |

Cutting Speed

Laser cutting is generally faster than waterjet cutting, especially for thinner materials. If you have time-sensitive projects or need high production throughput, laser cutting may be more suitable.

Edge Quality

Waterjet cutting produces a smooth, sandblasted edge, while laser cutting can provide a precise, clean edge. Consider the desired edge quality for your project and select the method that best matches your requirements.

Environmental Impact

Waterjet cutting is considered more environmentally friendly compared to laser cutting. Waterjet cutting uses water as the primary cutting medium and does not produce harmful fumes or gases. Laser cutting, on the other hand, may release fumes and requires appropriate ventilation and exhaust systems.

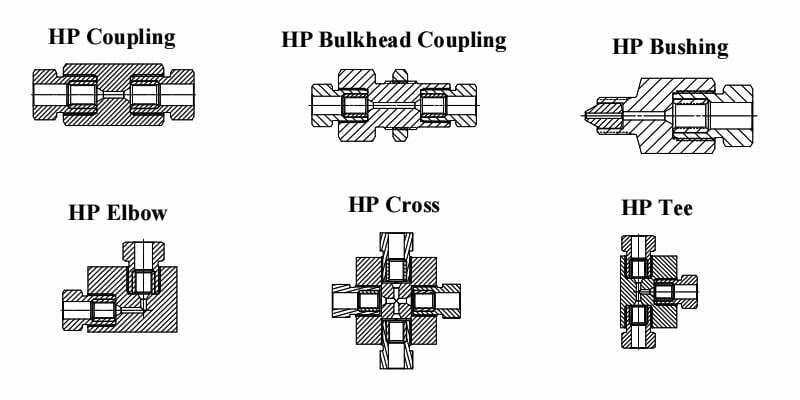

High Pressure Fitting and Valve Assemblies

HP Coupling

| 10079028 | Coupling, .25 x .25, F/F | 10079614 | Coupling, .38 x .25, F/F |

| 10078905 | Coupling, .38 x .38, F/F | 10078145 | Coupling, .56 x .25, F/F |

| 10079531 | Coupling, .56 x .38, F/F | 10078640 | Coupling, .56 x .56, F/F |

HP Bulkhead Coupling

| 10078160 | Bulkhead Coupling, .38 x .38, F/F | 10079705 | Bulkhead Coupling, .56 x .56, F/F |

| 49830581 | Bulkhead Coupling, .56 x .38, F/F | 20424785 | Bulkhead Coupling, .75 x .75, F/F |

HP Bushing

| 10079473 | Bushing, .38 x .25, F/M | 10079655 | Bushing, .56 x .38, F/M |

| 10079432 | Bushing, .38 x .25, M/F | 10079457 | Bushing, .56 x .38, M/F |

| 10079424 | Bushing, .56 x .25, F/M | 49832801 | Bushing, .75 x .56, F/M |

| 10079580 | Bushing, .56 x .25, M/F |

HP Elbow

| 10079051 | Elbow, .25 x .25, 90D | 10078525 | Elbow, .56 x .56, 90D |

| 10078780 | Elbow, .38 x .38, 90D | 49832645 | Elbow, .75 x .75, 90D |

HP Cross

| 10097228 | Cross, .25 | 10079168 | Cross, .56 |

| 10078038 | Cross, .38 | 49832652 | Cross, .75 |

HP Tee

| 10079481 | Tee, .25 | 10079465 | Tee, .56 |

| 10078590 | Tee, .38 | 49832660 | Tee, .75 |

Can you provide examples of materials that are compatible with both waterjet cutting and laser cutting?

Metals

Both waterjet cutting and laser cutting can be used for various types of metals.

including stainless steel, mild steel, aluminum, copper, brass, titanium, and more.

The choice between waterjet and laser cutting for metals depends on factors such as material thickness, desired edge quality, and project requirements.

Plastics

Many types of plastics can be cut using both waterjet and laser cutting methods. This includes acrylic, polycarbonate, PVC, nylon, ABS, and more. Laser cutting is often preferred for plastics due to its precision and ability to achieve intricate cuts.

Wood

Both waterjet cutting and laser cutting can be utilized for cutting different types of wood.

such as plywood, MDF (medium-density fiberboard), solid wood, and veneer.

Laser cutting is commonly chosen for wood due to its high precision and ability to create intricate designs

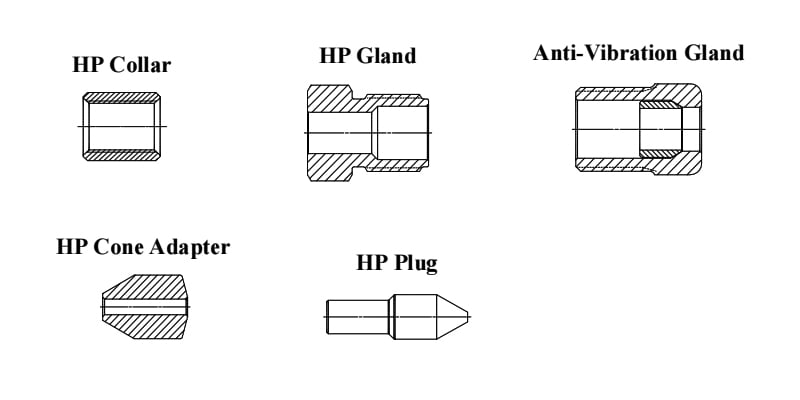

| 10078426 | Collar, .25 | 10078715 | Collar, .38 |

| 10079119 | Collar, .56 | 49832686 | Collar, .75 |

| 10078459 | Gland, .25 | 10078129 | Gland, .38 |

| 10078608 | Gland, .56 | 49832678 | Gland, .75 |

| 10116333 | Adapter Cone, .25 | 10078509 | Adapter Cone, .38 |

| 10079291 | Adapter Cone, .56 | 20448815 | Adapter Cone, .75 |

| 10078244 | Plug, .25 | 10079523 | Plug, .38 |

| 10078772 | Plug, .56 | ||

| 10078699 | Anti-Vibration Gland, .25 | 10078913 | Anti-Vibration Gland, .38 |

| 10093573 | Anti-Vibration Gland, .56 |

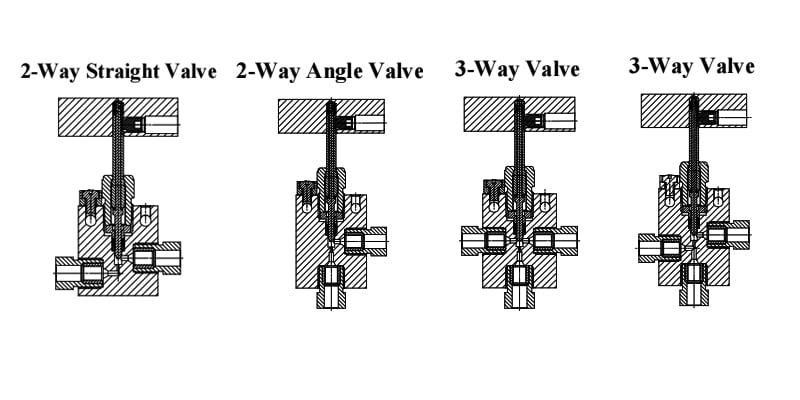

| 10079259 | 2 Way Straight, .25 | 10078889 | 2 Way Straight, .56 |

| 10078863 | 2 Way Straight, .35 | 20432554 | 2 Way Straight, .75 |

| 10097533 | 3 Way/1 Pressure Valve, .38 | 10097541 | 3 Way/1 Pressure Valve, .56 |

| 05137724 | 3 Way/2 Pressure Valve, .38 | 10153500 | 3 Way/2 Pressure Valve, .56 |

| 10079002 | 2 Way Angle, .25 | 10078749 | 2 Way Angle, .38 |

| 10079275 | 2 Way Angle, .56 |

Glass

Waterjet cutting and laser cutting can be employed for cutting glass materials.

Waterjet cutting is often used for thicker glass.

Laser cutting is preferred for thinner glass, intricate patterns, or delicate designs.

Stone

Waterjet cutting is particularly suitable for cutting stone materials, including granite, marble, slate, and others.

Laser cutting can also be used for certain types of stone,But it may generate heat and cause thermal effects.

so it is important to consider the stone’s heat sensitivity and the desired cutting precision.

Composites

Both waterjet cutting and laser cutting can be used for cutting composite materials, such as carbon fiber, fiberglass, and laminates. The choice between the two methods depends on factors such as material thickness, desired edge quality, and project requirements.