توفر WINWIN ترقية تقنية لملك الفولاذ والحديد

For metals like titanium, steel, brass, or aluminum, waterjet is the most versatile cutting method available.

Waterjet tables can be used to cut thicker metals than can be processed with a laser – like titanium and aluminum (up to 12”/305mm)– and offer greater precision than plasma cutting.

Abrasive waterjet systems are also less expensive than laser solutions, making them a solid choice for metal and steel cutting in the fabrication industry.

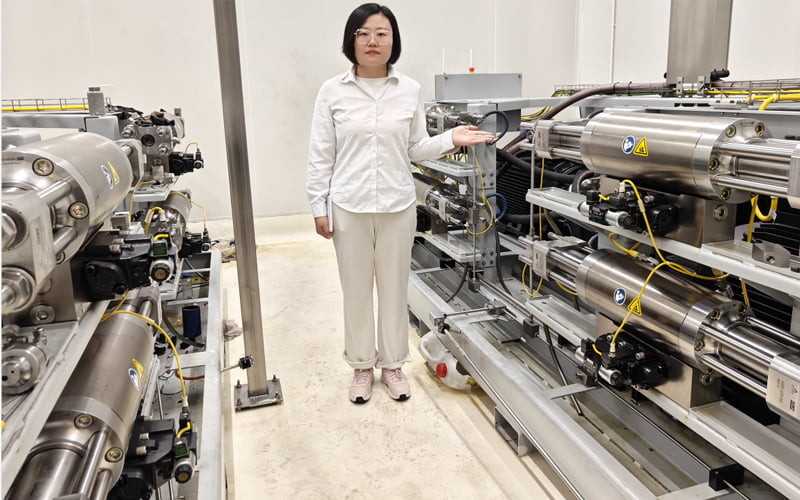

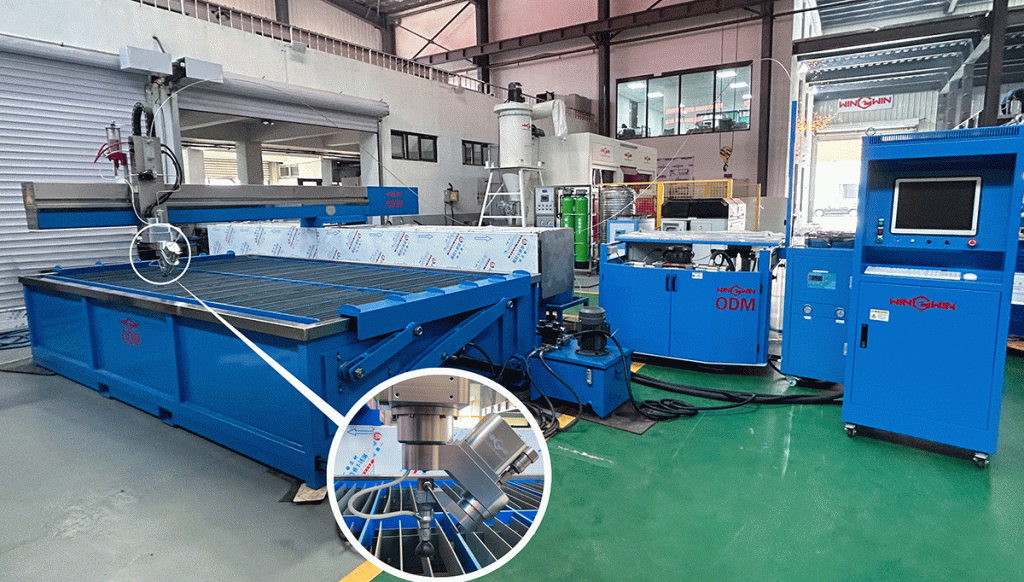

WINWIN Metal Cutting Systems

We utilize a network of reliable, highly trained professional waterjet system manufacturers who specialize in water jet machine technology. WINWIN OEM partner integrators will design and manufacture the waterjet cutting table system that works best for your metal cutting application, and will ensure that you and your team are trained with all the tools and support you need for success and profitability.

Waterjet cutting is a method of cutting materials using a high-pressure water stream, including cutting iron. It utilizes high-pressure water flow and an abrasive mixture (such as garnet) to erode and cut materials with high precision and flexibility.

The following are the general steps for waterjet cutting of iron:

Material preparation: Clean the surface of the iron plate . iron material to be cut and fix it on the water cutting workbench.

CAD Design: Create or prepare a computer-aided design (CAD) file specifying the desired cutting shape or pattern. This file is very important for programming your waterjet machine.

Machine settings: The waterjet cutting machine is programmed according to the CAD file .

the file will to set cutting parameters such as cutting speed, pressure and nozzle position.

Cutting process: The waterjet cutting machine sprays a mixture of high-pressure water flow and abrasive onto the iron material,

It gradually cuts the material through the impact of the water flow and the grinding effect of the abrasive.

The nozzle can move along a predetermined path to achieve the desired cutting shape.

Finishing and Cleaning: Once the cut is complete, remove the cut iron and clear the cut area of waste and residue.

Waterjet cutting of iron has many advantages, including no heat-affected zone, high precision, fast cutting speed, and no need for secondary processing. However, with thicker iron or particularly hard steel, higher pressure and greater abrasive concentration may be required to cut effectively.

The maximum thickness of iron that can be cut

with a waterjet depends on several factors, including the power of the waterjet machine, nozzle diameter, cutting speed and the type of abrasive used.

Typically, the maximum thickness that waterjet can be used to cut iron is about 150 mm (6 inches). However, it should be noted that cutting thicker iron may require higher water pressure and greater abrasive concentration to ensure cutting speed and quality.

For iron that exceeds the maximum thickness of waterjet cutting, you may want to consider other cutting methods, such as plasma cutting or flame cutting, which can handle thicker metal materials.

Water cutting, plasma cutting, and flame cutting are all common metal cutting methods, and each has some advantages and disadvantages. Here are some of the main advantages and disadvantages of water cutting over plasma and oxyfuel cutting:

Advantages of waterjet cutting:

No heat-affected zone: Water cutting is a cold cutting process that has no obvious heat-affected zone, so it can avoid material deformation, hardening or cracking.

High precision: Water jet cutting can achieve high-precision cutting, usually with small cutting gaps and excellent cut quality.

Multi-material applicability: Water cutting is suitable for various materials, including metal, plastic, stone, composite materials, etc.

Non-toxic and harmless: No toxic or harmful chemicals are used in the water cutting process, making it environmentally friendly.

Disadvantages of waterjet cutting:

Slower cutting speed: Compared to plasma cutting and flame cutting, water cutting has a slower cutting speed.

Limitations on material thickness:

The maximum cutting thickness of water jet cutting is relatively small, usually around 150 mm (6 inches).

High cost:

Waterjet cutting equipment and operating costs are relatively high, including costs for water sources, abrasives, and maintenance.

Plasma cutting and flame cutting may offer the following advantages in some aspects:

High-speed cutting:

Plasma cutting and flame cutting generally have faster cutting speeds and are especially suitable for thicker metal materials.

Suitable for high-thickness materials:

Plasma cutting and flame cutting can process thicker metal materials, and can reach cutting thicknesses of tens of millimeters to several meters.

However, plasma cutting and flame cutting also have some disadvantages, such as larger heat-affected zones, lower cutting accuracy, and possible oxidation on the cutting edges.

Selecting the appropriate cutting method should be evaluated based on specific needs and material characteristics to ensure optimal cut quality and efficiency.

Where to Find a CNC Waterjet Cutting Machine?

WINWIN WATERJET is one of the world’s leading brands in the field of water jet cutting technology. We offer a wide range of water jet cutting systems.

the system covering a wide range of applications including manufacturing, aerospace, automotive, marine, electronics, stone processing and more. WINWIN WATERJET’s products feature high precision, high efficiency and reliability.

WINWIN technicians are invited to snorkel after the Marine industry Customer Project is installed.