Internationales Konsortium investiert Kapital in WINWIN Waterjet

The origin of water jet cutting technology

The origins of water jet technology can be traced back to the mid-20th century. Water jet cutting is a technology that uses high-pressure water jets to cut, clean and process materials.

The following is the historical development of water jet cutting technology:

It has some unique advantages, including suitability for a variety of materials, no heat-affected zones (thermal stress), and high precision.

1940s and 1950s: The earliest high-pressure water jet technology was mainly used in the cleaning and drainage fields. Early water jet systems had relatively low pressures and were used to clean pipes and other equipment.

1960s: Advances in high-pressure pump technology increase the pressure and speed of water jets, giving them the ability to cut through hard materials such as metal and stone.

1970s: Water jet technology begins to be widely used in industry, especially in mining, quarrying and metal processing.

1980s: The increasing accuracy and controllability of high-pressure water jet systems allow them to be used for more delicate cutting tasks, such as cutting automotive parts and aerospace materials.

1990s and beyond: Water jet technology is used in a wide range of applications, including manufacturing, construction, aerospace, medical device manufacturing, and the arts. High-pressure water jet technology continues to evolve, including research into adding abrasives to the water jet to enhance cutting capabilities.

The continuous development of water jet technology has enabled the development of modern manufacturing and engineering, making it a flexible, efficient and precise method of processing materials that can be applied to a variety of industries and tasks.

Introduction to Winwin waterjet Co.,Ltd.

WINWIN WATERJET is a china-leading high-pressure water jet cutting technology company, specializing in the design and manufacture of high-pressure water jet cutting systems and related equipment.

Company History: WINWIN WATERJET was established in 2011 and is headquartered in Shenyang, China. Since its establishment, the company has been committed to the research, development and innovation of water jet technology and has established a global sales and service network.

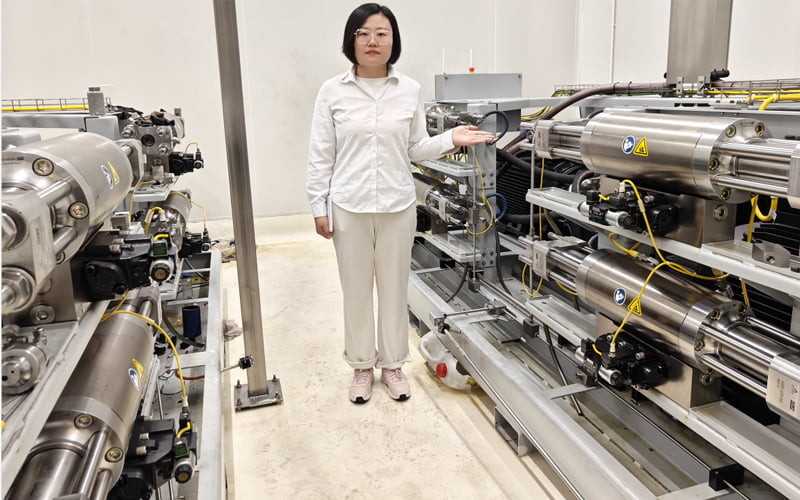

Technology and products: winwin waterjet provides a series of high-pressure water jet cutting systems,

1. robotic water jet cutting systems

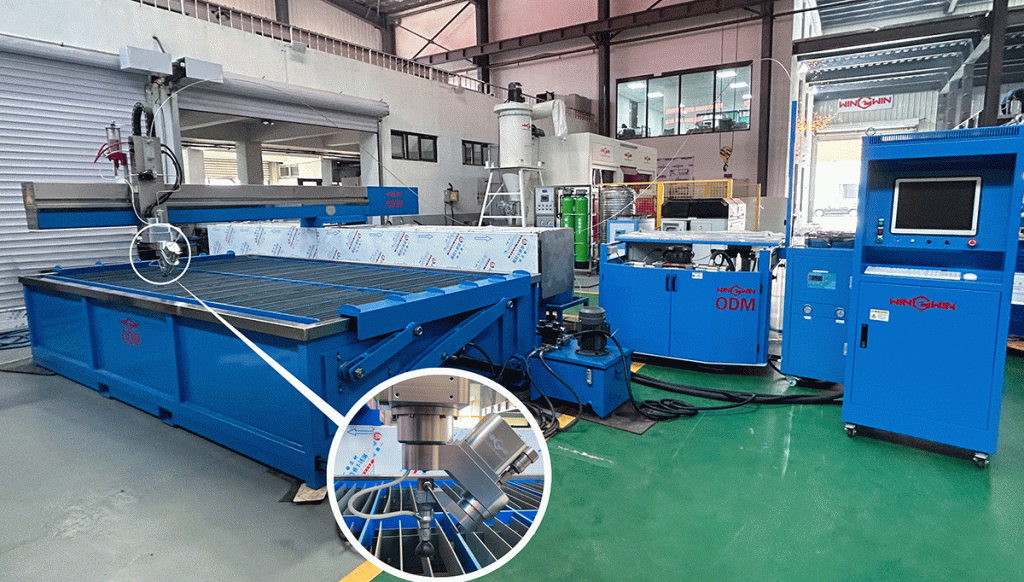

2. platform water jet cutting systems

3.water jet cutting intensifier pumps

4. water jet cutting accessories

5. water jet cutting cleaning, etc.

The company’s products are widely used in cutting various materials, including metal, stone, composite materials, glass, plastic, etc.

Application fields: WINWIN water jet technology is widely used in various fields, including manufacturing, automotive industry, aerospace, construction industry, etc.

It can achieve high-precision cutting, processing of complex contours, and layered cutting of material stacks to meet the needs of different industries.

Innovation and Sustainability: winwin waterjet continuously conducts research and innovation to improve the performance and efficiency of water jet technology and is committed to sustainability. They focus on reducing water and energy consumption, as well as recycling and reusing materials.

Winwin waterjet enters Vietnam market

Winwin waterjet is committed to the development of the Southeast Asian market.

The manufacturing industry in Southeast Asia has achieved significant development in the past few decades, attracting a large amount of domestic and foreign investment and becoming one of the important centers of global manufacturing. WINWIN waterjet in Vietnamese market has a wide range of applications, covering multiple industries and fields.

Manufacturing:

Water jet cutting equipment is widely used in Vietnam’s manufacturing industry for cutting materials such as metal, plastic, rubber, and composites. It can be used for tasks such as manufacturing parts, assembling materials, and prototyping. Vietnam’s manufacturing industry includes automobile manufacturing, electronic manufacturing, machinery manufacturing and other fields.

Construction and Decoration:

Water jet technology is used to cut and process construction materials such as marble, granite and ceramic tiles

in order to create decorative design elements such as patterns, carvings and decorative panels. This is common in the field of architecture and interior decoration in Vietnam.

Mining and Quarrying Industry:

Vietnam is rich in mineral resources, and water jet cutting technology can be used in quarrying and ore processing to obtain high-quality stone blocks for construction and carving.

Aerospace and Defense:

Water jet technology is used in Vietnam’s aerospace and defense sector to cut and process aerospace parts, armor materials and other critical components to ensure product accuracy and quality.

Food Processing:

Water jet technology also has applications in food processing.

such as cutting meat, vegetables, and baked products to achieve precise cutting and processing.

Art and Sculpture:

Artists and sculptors can use water jet technology to create intricate artwork and sculptural pieces as it allows for highly precise cutting and carving.

In general, water jet cutting technology is widely used in the Vietnamese market, meeting the needs of different industries and providing high-precision, high-efficiency and multi-material cutting solutions. As technology continues to develop, water jet cutting will continue to play an important role in various fields in Vietnam.

Winwin is invested in the Vietnamese market as an emerging company to implement automated, digital and intelligent manufacturing technologies.

Where to Find a CNC Waterjet Cutting Machine?

WINWIN WATERJET is one of the world’s leading brands in the field of water jet cutting technology.

We offer a wide range of water jet cutting systems.

the system covering a wide range of applications including manufacturing, aerospace, automotive, marine, electronics, stone processing and more. WINWIN WATERJET’s products feature high precision, high efficiency and reliability.

WINWIN technicians are invited to snorkel after the Marine industry Customer Project is installed.