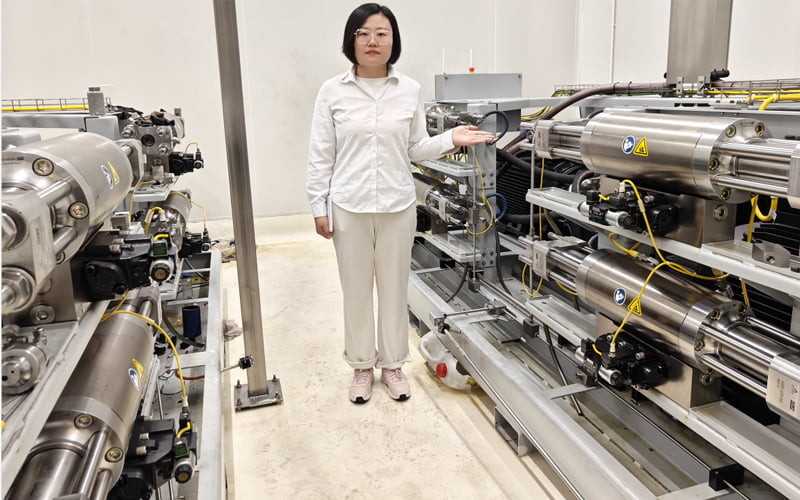

Waterjet parts Coil 106259 Fanuc Line 5

Item number: 106259

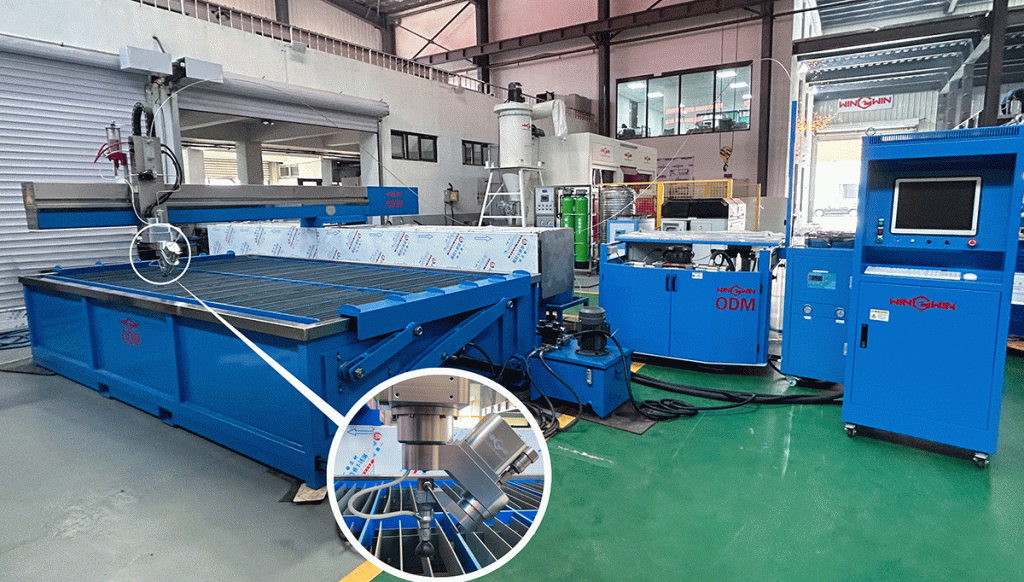

Details: Robotic Waterjet parts Coil 106259 used on FANUC robot waterjet cutting system

Made from 66K PSI or 100K PSI Tubing

Beschreibung

REPLACEMENT Robotic Waterjet parts Coil 106259

Robotic Waterjet parts Coil 106259 Description

Item number: 106259

Details: Robotic Waterjet parts Coil 106259 used on FANUC robot waterjet cutting system

Made from 66K PSI or 100K PSI Tubing

Pre-Coned and Threaded

Flushed under High Pressure prior to ship

With over 20 years of experience, WINWIN Waterjet has a large archive of coil drawings including:

ABB,FANUC,YASKAWA,KUKA Coils

Shape Process Automation (DRS, KMT, RPT) Coils

Flow Robotics Coils

And More

Andere Wasserstrahl-Hochdruckspulen für Fanuc-Roboter-Wasserstrahl

| 20480158 | Spulenachse 4,5,6 |

| M20-1-2-REV1 | Spulenachse 1,2 |

| M20-L-1CTREV1 | Spulenachse 1 |

| M20-M-2CT | Spulenachse 2 |

| M20-N-3CT | Spulenachse 3 |

| 104509 | Spule Fanuc 1 |

| 104510 | Spulenachse 2 |

| 104511 | Spule Fanuc 3 |

| 104521 | Spule Fanuc 4 |

| 104522 | Spule Fanuc 3 |

| 104536 | Spule Fanuc 2 |

| 104537 | Spule Fanuc 5 |

| 104557 | Spule Fanuc 1 |

| 104745 | Spule Fanuc Linie 4 |

| 104746 | Spule Fanuc Linie 5 |

| 104780 | Spule Fanuc 2 |

| 104786 | Spule Fanuc M20 M4,5,6 |

| 106259 | Spule Fanuc Linie 5 |

| 106260 | Spule Fanuc Linie 4 |

| 107158 | Spule Fanuc ändern 104746 |

How to choose robotic waterjet cutting machine?

Choosing a robotic waterjet cutting machine involves considering several key factors to ensure that it meets your specific needs and delivers the best results for your application. Here’s a step-by-step guide on how to choose a robotic waterjet cutting machine:

- Identify Your Application and Requirements:

- Determine the type of materials you need to cut (e.g., metal, stone, composites).

- Understand the thickness and size of the materials.

- Identify the desired precision and cutting speed.

- Determine the level of automation required and the complexity of the cuts.

- Budget and ROI Analysis:

- Establish a budget for the robotic waterjet system, including installation and ongoing operational costs.

- Perform a return on investment (ROI) analysis to assess the cost-effectiveness of the machine for your specific needs.

- Choose the Right Robot:

- Select a robot with the appropriate payload capacity and reach to handle your workpieces and perform the required tasks.

- Select the Appropriate Waterjet Cutting System:

- Choose a waterjet cutting system that matches your material, thickness, and precision requirements. Waterjet systems can vary in terms of pump pressure, nozzle types, and cutting heads.

- Software Compatibility:

- Ensure that the robot and waterjet system are compatible with your CAD/CAM software for programming and controlling the cutting process.

- Robot Integration:

- Consider the ease of integrating the robotic arm with the waterjet system. Compatibility and communication between the robot and the cutting equipment are critical.

- Safety Features:

- Verify that the machine has adequate safety features to protect both operators and the equipment. This may include emergency stop buttons, safety interlocks, and protective barriers.

- Maintenance and Support:

- Evaluate the manufacturer’s reputation for customer support, maintenance services, and the availability of replacement parts.

- Training and Operator Expertise:

- Ensure that your team is trained to operate and maintain the robotic waterjet system. Operator expertise is crucial for safe and efficient operation.

- Environmental Considerations:

- Assess the machine’s environmental impact, including noise levels, dust collection, and wastewater disposal.

- References and Reviews:

- Seek references and customer reviews from other users of the same machine to gauge its performance and reliability.

- Warranty and Service Agreements:

- Review the warranty and service agreements provided by the manufacturer to protect your investment.

- Testing and Trials:

- If possible, conduct testing and trials with the machine on your specific materials and parts to ensure it meets your quality and performance requirements.

- Future Expansion and Scalability:

- Consider the potential for expanding your system in the future to accommodate increased production demands.

By following these steps and conducting thorough research, you can select a robotic waterjet cutting machine that best matches your application and operational needs, providing you with precision, efficiency, and reliability in your cutting processes.

If you are looking for robot waterjet cutting system suppliers or Waterjet parts Coil 106259 suppliers, as well as waterjet technical support needs related to water cutting, please feel free to contact us, we can provide free online support for you.

Bewertungen

Es gibt noch keine Bewertungen.