Charles -Promotion of waterjet robot cell

Hobbies: fitness, reading

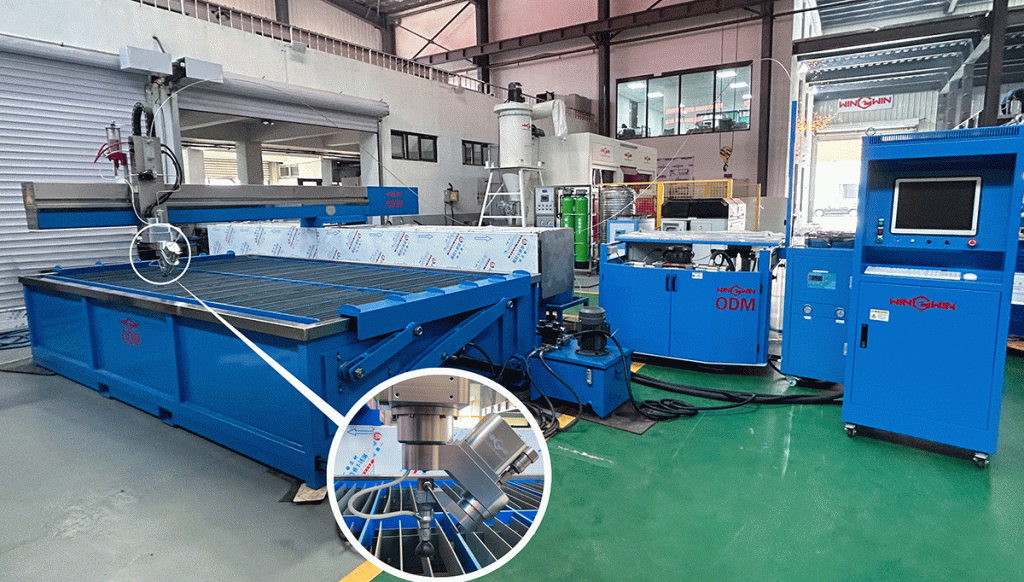

Products sold: Waterjet Robot Cell

Service industry: Automotive interior ceiling carpet company

I usually like fitness and reading, and I am passionate about life. Worked at winwin waterjet for more than 10 years, responsible for the promotion and service of Waterjet Robot Cell products.

As a fitness enthusiast, Charles focuses on keeping his body healthy and strong. He regularly participates in fitness activities, exercises, and maintains good physical fitness and a healthy lifestyle. This positive attitude towards life is also reflected in his work, where he is committed to providing customers with high-quality and efficient solutions.

In addition to fitness, Charles is also an avid reader. He enjoys reading widely across a variety of genres, including those in technology, business, and innovation. This allows him to continuously update his knowledge and apply it in his work to drive development and innovation of Waterjet Robot Cell products.

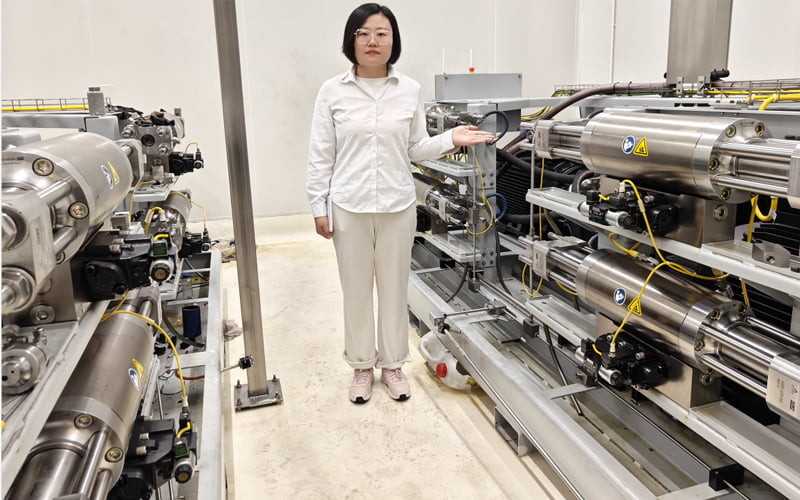

Waterjet Robot Cell is an advanced robotic system for automotive interior manufacturing. It combines waterjet technology with automated robotic operations to precisely cut, engrave and process materials such as ceilings and carpets. I am responsible for promoting and servicing this product, working with customers to understand their needs and ensuring that the Waterjet Robot Cell meets their requirements.

In the automotive interior headliner and carpet company, I provide customers with high-quality and customized interior products through the application of Waterjet Robot Cell. I make a significant contribution to the company’s success and client satisfaction through my expertise and enthusiasm.