107504 Coil R-Axis HP20 040253-1 Robotic Water jet Coils

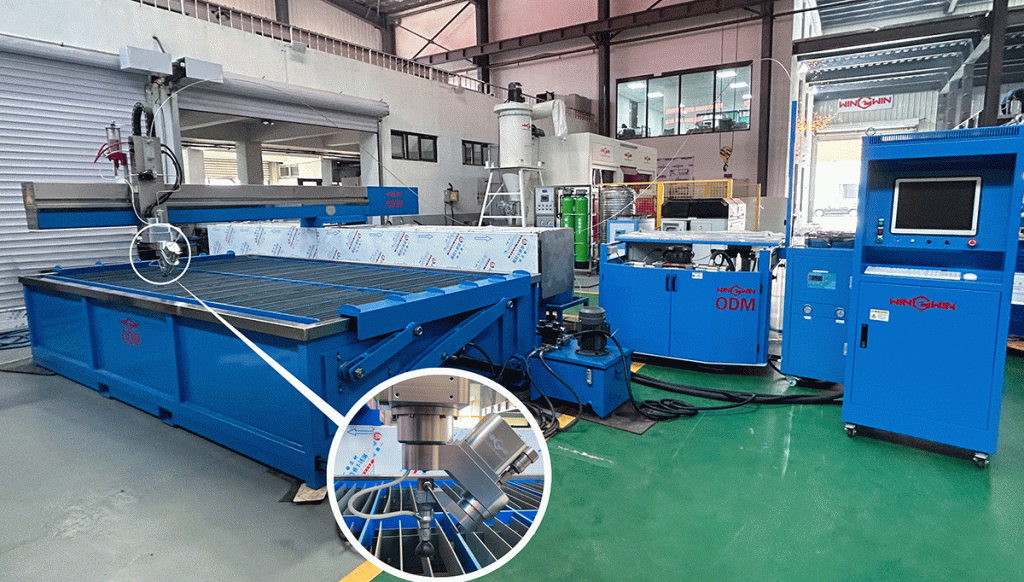

Details: robotics water jet coils used on robot waterjet cutting system

Made from 66K PSI or 100K PSI Tubing

Pre-Coned and Threaded

Flushed under High Pressure prior to ship

With over 20 years of experience, WINWIN Waterjet has a large archive of coil drawings including:

ABB,FANUC,YASKAWA,KUKA Coils

Shape Process Automation (DRS, KMT, RPT) Coils

Flow Robotics Coils

And More

Beschreibung

REPLACEMENT Robotic Water jet Coils

Description

Details: robotics water jet coils used on robot waterjet cutting system

Made from 66K PSI or 100K PSI Tubing

Pre-Coned and Threaded

Flushed under High Pressure prior to ship

With over 20 years of experience, WINWIN Waterjet has a large archive of coil drawings including:

ABB,FANUC,YASKAWA,KUKA Coils

Shape Process Automation (DRS, KMT, RPT) Coils

Flow Robotics Coils

And More

How to maintain robot waterjet cutting system? (WINWIN can customize Robotic Water jet Coils)

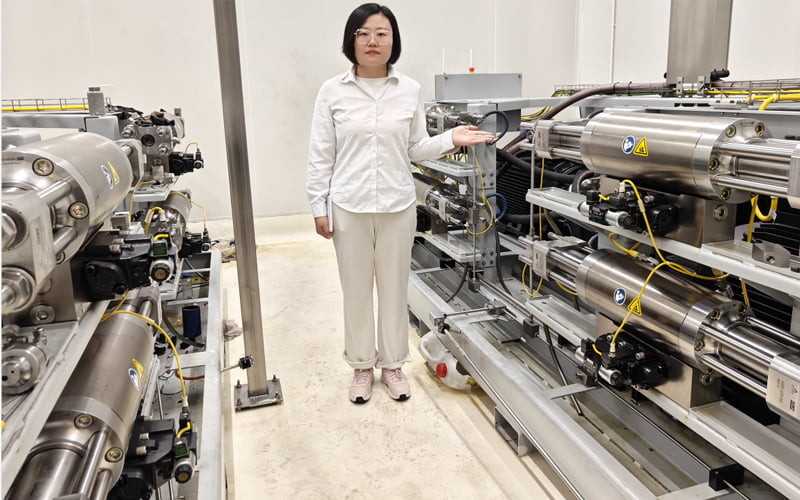

Robotic water jet coils are important consumables in the maintenance of the robot waterjet cutting system. WINWIN has the following suggestions for maintaining the robot water cutting system.

Maintaining a robot waterjet system is essential to ensure its optimal performance, extend its lifespan, and prevent unexpected downtime. Regular maintenance helps prevent wear and tear on components and reduces the risk of costly breakdowns. Here are some key maintenance steps for a robot waterjet system:

Establish a Maintenance Schedule:

Create a maintenance schedule based on the manufacturer’s recommendations and the system’s usage. Regular maintenance can be daily, weekly, monthly, or as needed, depending on the intensity of use.

Clean the System:

Regularly clean the robotic arm, cutting head, and the surrounding work area to remove any accumulated debris, dust, or abrasive residues. Ensure that all moving parts are free from obstructions.

Inspect Hoses and Fittings,Robotic Water jet Coils:

Check high-pressure hoses, fittings, and connections Robotic Water jet Coils for signs of wear, leaks, or damage. Replace any damaged components promptly to prevent water or abrasive leakage.

Examine Nozzles and Orifices:

Inspect the cutting head’s nozzles and orifices for wear, cracks, or blockages. Replace them if necessary to maintain the quality of the waterjet stream.

Check O-Rings and Seals:

Examine O-rings and seals in the cutting head and high-pressure components for signs of wear or deterioration. Replace any damaged seals to prevent water or abrasive leaks.

Abrasive Management:

If abrasive cutting is used, manage the abrasive materials efficiently. Ensure that abrasive feed systems and removal systems are functioning correctly.

Pump Maintenance:

If your system includes a waterjet pump, follow the manufacturer’s guidelines for pump maintenance, which may include oil changes, seal replacements, and other routine tasks.

Lubrication:

Lubricate the robot arm’s joints and bearings according to the manufacturer’s recommendations. Proper lubrication helps prevent excessive wear.

Water Quality:

Maintain the quality of the water supply, which is essential for the cutting process. Use a water filtration and treatment system to remove impurities and ensure consistent water quality.

Software Updates:

Keep the CNC control system software up to date to benefit from improvements, bug fixes, and enhanced features. Work with the system manufacturer to schedule updates.

Training:

Ensure that personnel operating and maintaining the robot waterjet system are well-trained and familiar with the system’s components and maintenance procedures.

Emergency Procedures:

Establish clear emergency procedures in case of equipment malfunctions or unexpected situations. Train operators on how to respond to various scenarios.

Documentation:

Maintain records of maintenance activities, including dates, repairs, replacements, and any issues encountered. This documentation can help track the system’s history and plan for future maintenance.

Professional Service:

When in doubt or for more complex maintenance tasks, consult with the system manufacturer or a qualified technician who specializes in robotic waterjet systems.

Regular maintenance of your robot waterjet cutting system is essential for safety, efficiency, and the longevity of the equipment. By following a structured maintenance schedule and addressing issues promptly, you can ensure that your system continues to operate at peak performance.

If you are looking for robot waterjet cutting system suppliers or Robotic Water jet Coils suppliers, as well as waterjet technical support needs related to water cutting, please feel free to contact us, we can provide free online support for you.

Bewertungen

Es gibt noch keine Bewertungen.