Maintenance and consumables for hpp machines

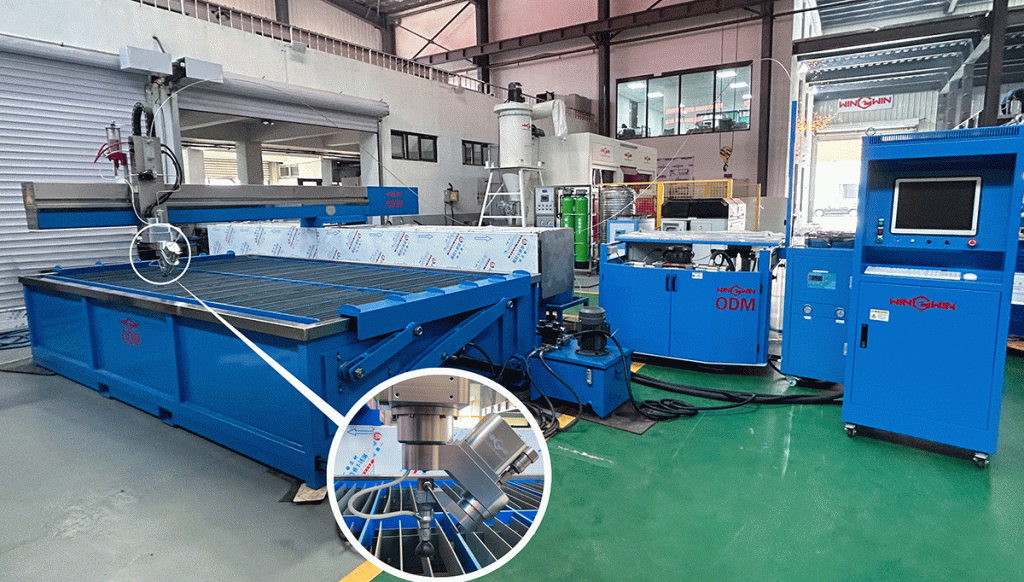

Why choose win-win waterjet parts for HPP machine

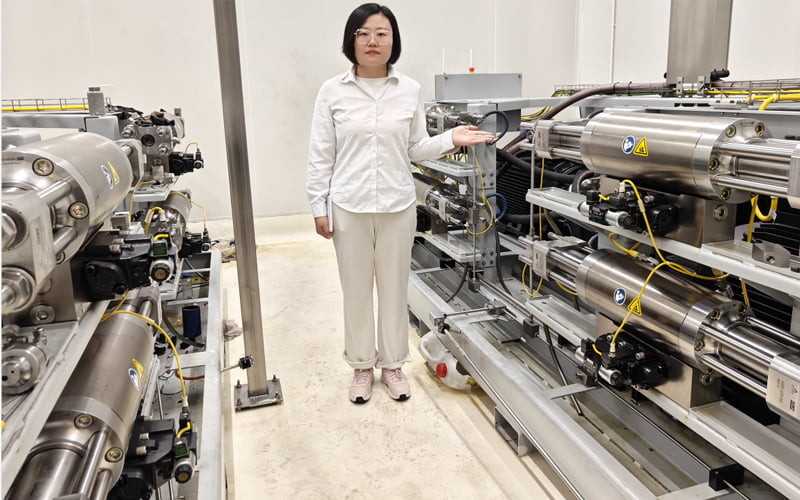

Win-Win recognize that when the pressure is not working, your HPP Machines are not processing product. Win-Win HPP machine parts is our solution to ensuring your machines uptime.

WHY Win-Win HPP machine parts

Win-Win material Suppliers have been in the machine metal service for over a combined 60 years . This commitment to utilizing the most experienced Craftmanship allows Win-Win HPP parts to produce only the highest quality HPP Aftermarket Wear Parts, such as, High Pressure Tubing, Fittings, Intensifier Parts, Flow and Decompression Parts for the HPP Food Industry.

Avure Equipment users are the pioneers in the HPP Food Industry having HPP Equipment as far back as 2007, it is their invaluable insight that is the backbone to our platform of High Pressure Parts for the Avure/JBT AV-M and AV-X Models. These same users that provide their wealth of experience in maintaining these machines, also provide the rigorous field testing that is needed before any product is introduced into the marketplace.

WIN-WIN have a lot of experience for the Food Industry. Our parts are tailored to the Industry Standard Operating Pressure of 90,000 psi/620 MPa. It is for this reason we can offer HPP Aftermarket Wear Parts to our customers at affordable pricing over the OEM.

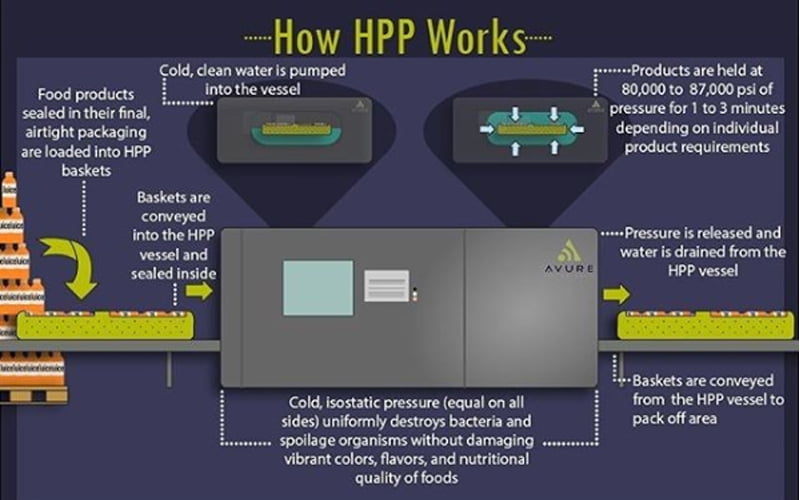

How HPP machine works

HPP systems neutralize listeria, E. coli, bacteria and salmonella, by processing foods with water pressurized up to 90,000psi by Waterjet intensifier.

HPP, which stands for High-Pressure Processing, is a food processing technique that uses high levels of pressure to preserve and extend the shelf life of food products. It is also known as high hydrostatic pressure processing or ultra-high pressure processing.

Here’s how HPP works:

Preparing the food:

The food to be processed is first prepared by cleaning, trimming, and packaging it in a suitable container, such as a flexible plastic pouch or a sealed bottle. The packaging must be impermeable to water and air.

Loading into the HPP vessel:

The packaged food is loaded into a high-pressure vessel, which is typically a cylindrical chamber made of stainless steel. The vessel is designed to withstand extreme pressure.

Pressurization:

Once the food is loaded, the vessel is sealed, and water or a food-grade liquid is used to fill the chamber. The vessel is then pressurized by applying pressure through the liquid using a high-pressure pump. Pressure levels used in HPP can range from 100 to 900 megapascals (MPa) or more, which is equivalent to 1,500 to 130,000 pounds per square inch (psi).

Holding time:

After reaching the desired pressure, the food is held at that pressure for a specific period, typically ranging from a few seconds to a few minutes. The exact duration depends on factors such as the type of food, its size, and its desired shelf life.

Pressure release:

Once the holding time is complete, the pressure is released by slowly releasing the pressure from the vessel. The pressure is gradually reduced to atmospheric levels, allowing the food package to be safely removed.

Packaging and distribution:

After HPP, the food is typically removed from its original packaging and repackaged for distribution. This step ensures that any potential microbial contamination from the original packaging is eliminated. The repackaged food is then distributed to retailers or consumers.

HPP is effective in preserving the quality and extending the shelf life of many food products, including juices, sauces, dips, meats, seafood, and ready-to-eat meals. It works by inactivating or destroying bacteria, yeasts, molds, and other pathogens that can cause spoilage or foodborne illnesses. The advantage of HPP is that it does not rely on heat, preserving the nutritional value, flavor, and texture of the food better than traditional thermal processing methods.

Where can get the HPP machine parts?

winwin is a manufacturer and supplier specializing in 90000psi ultra-high pressure parts. As an industry leader, we are committed to providing high-quality accessories and solutions to ultra-high voltage equipment manufacturers and maintenance service providers around the world. Our company was established in 2011 and has been focusing on the ultra-high voltage field for many years to meet customers’ needs for high quality and reliability.

Product and service:

We offer a wide range of ultra-high voltage accessories covering a variety of industries and applications. Our products include but are not limited to the following:

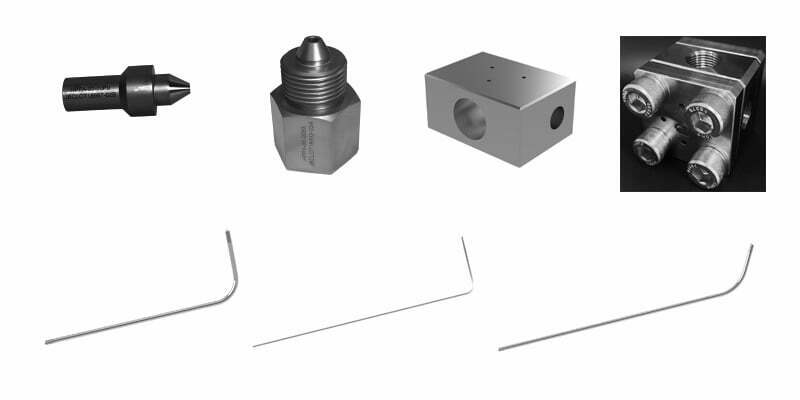

90000psi ultra-high pressure high pressure pump parts:

We provide various key parts of high pressure pumps, such as pistons, seals, plugs, etc.

High-pressure connection accessories:

We produce and supply high-strength, pressure-resistant high-voltage connection accessories, such as high pressure tube, tee, elbow, gland nut and collar connection parts, etc.

Control system components:

We provide control system components for ultra-high pressure equipment, such as pressure sensors, control valves, pressure instruments, etc.

Custom Accessories:

We also provide customized ultra-high voltage accessory solutions based on customer needs to meet specific application requirements.

| AT01403 | 9/16″ Tee | A-2839 | 3/8″ collar |

| 017252-1 | 3/8″ Plug | AT01259 | 3/8″ Gland Nut |

| 012252-1 | UHP 3/8″ Plug | AT01260 | 3/8″ collar |

| AT01263 | 9/16″ Plug, UHP | AT01409 | 9/16″ Gland nut |

| HPPA-00-00G3 | Ultra high pressure 3/8″ gland nut,UHP | AT01408 | 9/16″COLLaR |

| HPPA-00-00C3 | Ultra high pressure 3/8″ Collor,UHP | AT01261 | 9/16″ gland nut |

| A-2838-HPE | 3/8″ Gland Nut | AT01262 | 9/16″ collor |

| HPPA-00-0093 | 9/16″ to 3/8″ adapter | HPPA-00-PTA3 | adapter |

| HPPA-00-GCE3 | 3/8″ ELBOW | AT01400 | 3/8″*9/16″ Tee |

| AT01401 | 3/8″ TEE | AT01402 | 9/16″ Elbow,UHP |

| AT01403 | 9/16″ TEE | AT01403R | Reducer 9/16″ tee |

| AT01411 | Cross UHP,.56,F,SST,101KSI | 014523-1 | 3/8″ CROSS Truss |

| HPPA-AV-00E3 | 3/8″ ELBOW 101K | HPPA-AC-GCT3 | 3/8″ TEE 101K |

Advantages of WINWIN :

High quality and reliability:

Our accessories use high-quality materials and advanced manufacturing processes to ensure their high quality and reliability. We strictly implement quality control standards to ensure that each accessory meets customer expectations and requirements.

Technical Expertise:

We have a highly skilled team with extensive experience in the ultra-high voltage field. They are able to provide customers with professional technical support, consultation and solutions.

Customer Customization:

We fully understand each customer’s unique needs and provide customized accessory solutions. We work with our customers to ensure accessories are a perfect match for their equipment.

Timely Delivery:

We focus on punctuality and reliability of delivery. Our supply chain management and logistics teams ensure timely delivery of parts to customers.

For more information or to order our ultra-high voltage accessories, please feel free to contact our sales team. We look forward to working with you and providing the best accessory solutions for your ultra-high voltage equipment.