Sistema de corte por chorro de agua con robot tipo pedestal ABB 4600

Robot waterjet cutting system combine the versatility of waterjet with the smart manufacturing power of automation, increasing manufacturing flexibility, capacity, and output. Highly recognized as the most versatile shape processing solution, waterjet cuts virtually any material, any shape – with ease.

From 2-dimensional flat stock to 3-dimensional molded components, metals to fabric, plastic composites, and food, waterjet is an effective, efficient cutting solution.

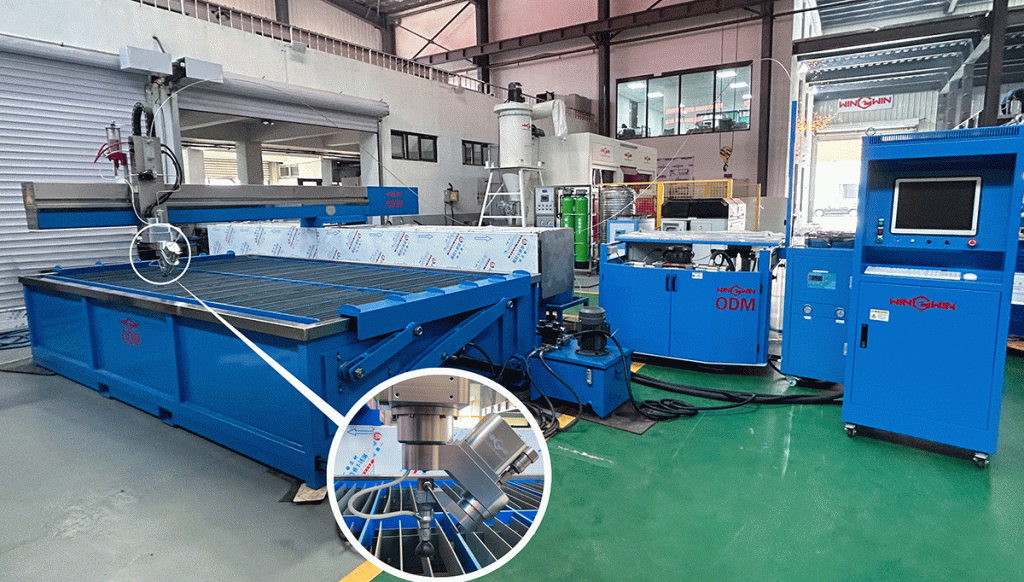

Today let’s take a look at this new set of robot waterjet cutting system.We customized for customers who use robotic water cutting system for automotive interiors processing.

| 1 | Brand of robot arm: | ABB | |

| 2 | Model: | 4600 | |

| 3 | Style: | Pedastal | |

| 4 | Quantity of robot arm: | Double | |

| 5 | Application: | Automotive interior cutting | |

| 6 | Pump type: | Scremline Pro 90k psi | |

| 7 | Oprator required: | 2 sets | |

| 8 | Customize avialable: | Yes | |

| 9 | Including devices: | Robot arm, cutting table, high-pressure pump, chiller, control system, etc.. | |

Is robot plus waterjet cutting a better processing method?

As we all know, robots are very common in the production of enterprises. They have the advantages of high precision, flexibility, and the ability to achieve tasks that humans cannot complete.

As the name implies, waterjet cutting uses water as the medium to cut materials. It has the advantages of not changing the physical and chemical properties of the material itself, flame-proof and explosion-proof, and pollution-free.

Back to our original question,the answer to this question: Yes.

The robot waterjet cutting system can cut more flexibly, multi-angle processing is more accurate, and it combines the characteristics of waterjet cutting, it can cut some combustibles, which is impossible for traditional cutting methods of (grinding, oxyacetylene flame, etc.)

Configuración del sistema de corte por chorro de agua con robot

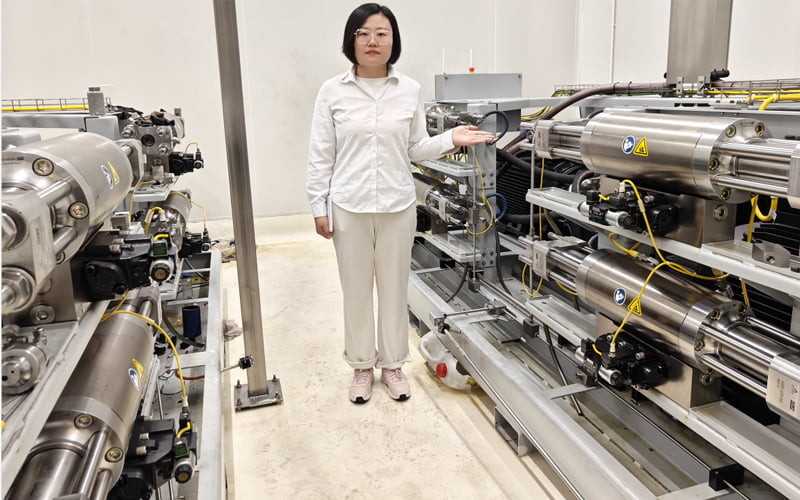

1: Estación de trabajo de pedestal

2: ABB 46000 robot arms of Robot Waterjet Cutting System

3: Equipado con bomba WIN-WIN de 90.000 psi

4: Enfriador industrial de alto rendimiento

5: El potente sistema de adsorción al vacío

6: Sistema de purificación de agua, que puede prolongar la vida útil del orificio.

7: Sistema de protección de seguridad para detectar personal en el área de trabajo y proteger la seguridad del personal.

8: sistema de control general

| Marca | GANAR GANAR | Modelo | Scrumlin Pro |

| Nombre | Bomba de chorro de agua de 90.000 psi | Temperatura | 5-40°C |

| Rango de presión | 90.000 psi (6.200 bares) | Control de nivel de aceite y temperatura | Sensor |

| Filtro de baja presión | 10 µm abs. | Solicitud | Sistema de corte por chorro de agua |

| voltaje | 380V | Potencia nominal | 60 caballos de fuerza (45 kw) |

| Capacidad del atenuador | 2L | Nom. Corriente a 480 V/60 Hz (amperio de carga completa) | 70 A |

| Flujo máximo de agua | 0,78 galones/min (2,9 lpm) | Mín. Cortar el flujo de entrada de agua | 4,0 galones (15,1 litros) |

| Capacidad del tanque hidráulico | 220L | Tamaño (largo * ancho * alto) | 2,2m*1,4m*1,5m |

| Peso | 1,5 toneladas |

What are the Characteristics of Robot Waterjet Cutting System?

1.Flexible Processing

The rapid development of the automobile industry. The rapid changes in production models.The needs of small and medium batches, and multiple varieties.

The robotic system is used as the actuator.And the types of processed parts can be replaced by changing the corresponding action program.

2.High stability

As the main body of the system, the Swedish ABB high-quality waterjet special high-performance robot (waterproof performance can reach the performance of putting all the robot in the water and then fishing them out without any treatment), PX high-quality high-pressure system, ultra-high pressure rotary valve and special tubing can minimize equipment failures and meet the needs of continuous production 24 hours a day.

3.High efficiency

The continuous working pressure of the system can reach more than 4000 bar.

The cutting speed is fast and the cutting quality is extremely good. At the same time, the fixed two-station workstation configuration is adopted. While one fixed workstation is cutting and processing.

The loading and unloading of the other fixed workstation is completed.

Which greatly reduces the waiting time of the equipment and improves the production efficiency.

4.Simple and convenient operation

All functional parts of the system are automated. After the positioning mold is replaced.

The corresponding processing program can be automatically called through the automatic identification function of the mold terminal. The operator only needs to operate the start and stop buttons on the control panel.

5.High security

safety protection fence and infrared isolation barrier are installed around the equipment. When a operator strays into the protection zone during the working process of the system.

The system will automatically shut down to protect the safety of the operator.complete alarm shutdown design, including water pressure, water shortage protection, etc.,

To ensure the safe operation of the whole machine, and when an alarm occurs.T=here are indicators that display the alarm content.So that the operator can quickly find and eliminate the fault.

6.Intelligentization

The automatic counting function is realized through the digital counter on the console.

And the operator can easily understand the number of cuts without manual counting.While the mold is installed on the workbench.The system can automatically identify the type of mold and automatically call the corresponding program.

7.System Composition

The robotic waterjet cutting system for cutting is composed of a high-voltage system.A robotic cutting unit and an electrical control unit. The function of the high-pressure system is to provide high-pressure water as an energy source.And the robotic cutting unit is the actuator. Which controls the spatial motion trajectory of the cutting head through programs. The electrical control unit is used to control the actions of high-voltage system, robot and functional components. According to the needs, the auxiliary system of the soft water system can also be selected according to the needs.

A continuación, echemos un vistazo a algunos de los problemas que preocupan a los clientes sobre el sistema robótico de corte por chorro de agua.