Waterjet Parts Coil 304296 Axis 2 ABB IRB1600

Item number:304296

Details: Robotic Waterjet parts Coil 304296 used on ABB IRB1600 Axis 2 robot waterjet cutting system

Made from 66K PSI or 100K PSI Tubing

Pre-Coned and Threaded

Flushed under High Pressure prior to ship

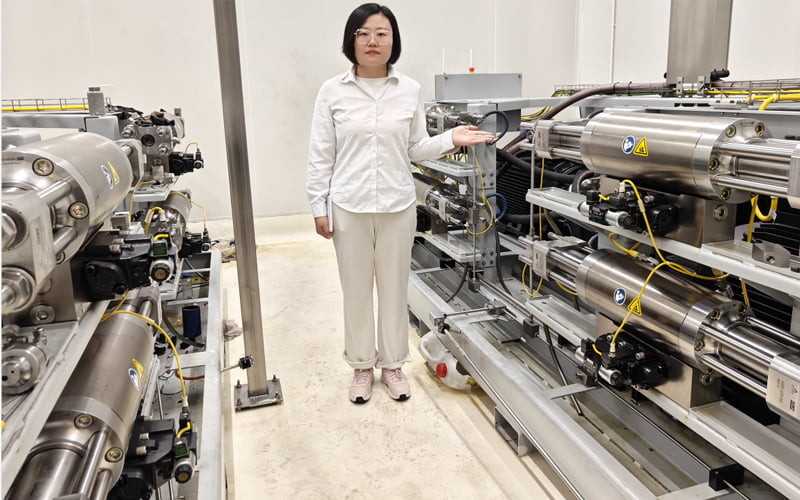

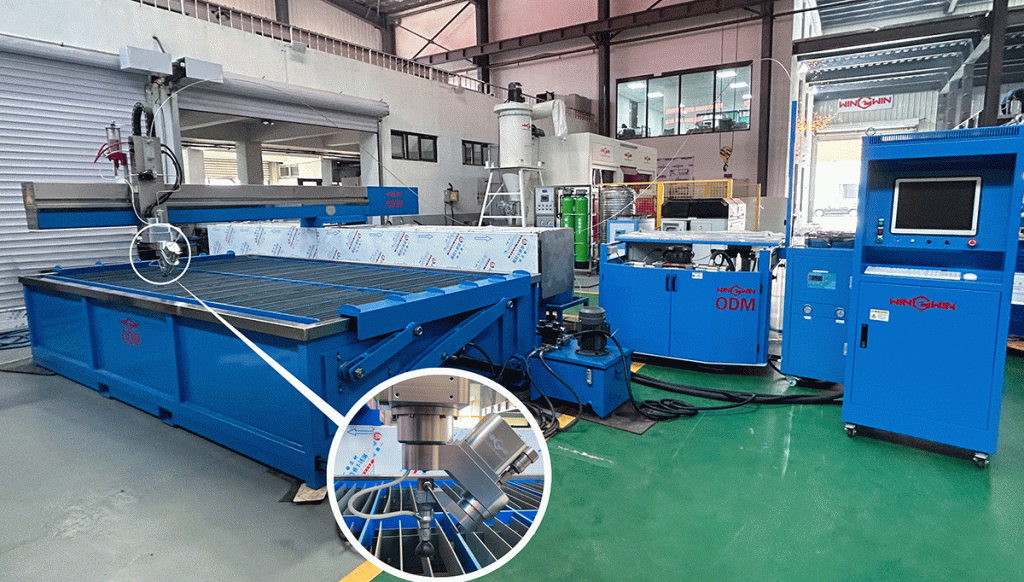

With over 20 years of experience, WINWIN Waterjet has a large archive of coil drawings including:

ABB,FANUC,YASKAWA,KUKA Coils

Shape Process Automation (DRS, KMT, RPT) Coils

Flow Robotics Coils

And More

Descripción

REPLACEMENT Robotic Waterjet parts Coil 304296

Robotic Waterjet parts Coil 304296 Description

Item number:304296

Details: Robotic Waterjet parts Coil 304296 used on ABB IRB1600 Axis 2 robot waterjet cutting system

Made from 66K PSI or 100K PSI Tubing

Pre-Coned and Threaded

Flushed under High Pressure prior to ship

With over 20 years of experience, WINWIN Waterjet has a large archive of coil drawings including:

ABB,FANUC,YASKAWA,KUKA Coils

Shape Process Automation (DRS, KMT, RPT) Coils

Flow Robotics Coils

And More

Other waterjet high pressure Coils for ABB 1600

| 304296 | Coil Axis 2 |

| 304297 | Coil Axis 3 |

| 304415 | Coil Axis 1 |

| 304436 | Coil Axis 4,5,6 |

| 305892 | Coil Axis 2 |

| 306337 | Coil Axis 1 |

| 104757 | Coil Axis 1 |

| 104758 | Coil Axis 2 |

| 104759 | Coil Axis 3 |

| 104760 | Coil Axis 4,5,6 |

| 106517 | Coil Axis 1 |

| 106671 | Coil Axis 2 |

| 107266 | Coil Axis 3 |

How to repair and maintain robotic waterjet machines

Maintaining and repairing robotic waterjet machines is essential to ensure their continued accuracy and efficiency. Regular maintenance can also extend the lifespan of the equipment. Here are some key steps and considerations for repairing and maintaining robotic waterjet machines:

Routine Maintenance:

- Check for Leaks:Inspect the entire waterjet system for any leaks, including high-pressure tubing, connectors, and seals. Repair or replace any damaged components immediately.

- Lubrication:Regularly lubricate the robotic arm’s joints and bearings as specified by the manufacturer’s guidelines to prevent wear and maintain smooth operation.

- Abrasive Removal System:If the machine uses abrasive waterjet cutting, regularly check and clean the abrasive removal system, which collects and recycles abrasive material.

- High-Pressure Components:Monitor high-pressure components, such as the intensifier pump, for any signs of wear or damage. Perform maintenance and replacements according to the manufacturer’s recommendations.

- Filters:Check and clean or replace filters in the water delivery system to ensure that the water remains clean and free of contaminants.

Scheduled Maintenance:

- Manufacturer’s Recommendations:Follow the manufacturer’s recommended maintenance schedule, which typically includes tasks like seal replacements, pump maintenance, and component inspections.

- Seal Replacements:Overhaul the entire waterjet system periodically to replace seals and O-rings as they wear over time. The frequency of seal replacements will depend on usage and the specific components involved.

- Software Updates:Keep the CNC control system software up to date to benefit from improvements, bug fixes, and enhanced features. Scheduled software updates are often released by the manufacturer.

Troubleshooting and Repairs:

- Diagnose Problems:If you encounter issues with the robotic waterjet machine’s performance, conduct a thorough diagnosis to identify the source of the problem. Common issues may include pressure loss, inaccurate cutting, or issues with the robotic arm.

- Consult Technical Documentation:Refer to the machine’s technical documentation and the manufacturer’s troubleshooting guide to help diagnose and fix problems.

- Professional Assistance:Some repairs and maintenance tasks may require the expertise of qualified technicians or service personnel. Consult with the manufacturer or a certified service provider for complex repairs or specialized maintenance.

Safety Precautions:

- Safety Procedures:Prioritize safety during maintenance and repair tasks. Follow recommended safety procedures, wear appropriate personal protective equipment, and ensure that the equipment is de-energized and depressurized.

- Operator Training:Ensure that operators and maintenance personnel are well-trained in the safe operation and maintenance of the machine.

Documentation:

- Record Keeping: Keep detailed records of maintenance and repair activities, including dates, tasks performed, and any replacement parts used. This documentation is valuable for tracking the machine’s history and performance.

Regular maintenance and prompt repairs are crucial for the reliable operation of robotic waterjet machines. Following the manufacturer’s guidelines and conducting routine checks and maintenance tasks can help prevent breakdowns and ensure that the machine continues to operate with precision.

If you are looking for robot waterjet cutting system suppliers or Robotic Water jet Coils suppliers, as well as waterjet technical support needs related to water cutting, please feel free to contact us, we can provide free online support for you.

Valoraciones

No hay valoraciones aún.