Pompe à jet d'eau WW 40 JET

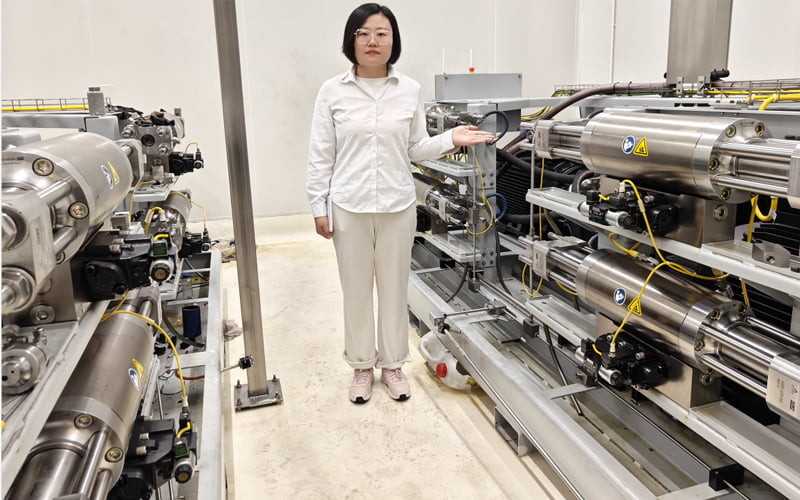

The WW 40 JET Waterjet Pump incorporates over 50 years of FLOW leading waterjet experience offering unparalleled waterjet cutting technological achievements. From the proven performance of our threaded high-pressure cylinders which eliminates any misalignment during assembly, to our leading-edge hydraulic control valve design that provides seamless, lag free topworks shifting, the WINWIN Series of pumps are Best in Class.

This WW 40 JET waterjet pump is widely used in many industries,such as metal,glass,marble,rubber,

automotive interior,.etc.

Key Features of 40 JET Waterjet Pump

- International high-level universal intensifier, imported spare parts.

- 420mpa high pressure, excellent cutting efficiency. Dual intensifier can work in the same time to increase productivity.

- 1L capacity accumulator, eliminate cutting fluctuation, integral forging, no rubber gaskets, no maintenance.

- Automatic shutdown of protection system when lack of water or overheating, it could work continuously and safely.

- Independent circulation filtration system, ensures the optimization of oil quality.

- Variablepiston pump, energy saving and heating, prolong the service life of hydraulic components.

| Marque | GAGNERGAGNER | Modèle | WW40JET |

| Capacité de l'atténuateur | 1L | Mode de conduite | Moteur haute performance |

| Voltage | 380V | Application | Système de découpe au jet d'eau |

| Puissance nominale | 30/40HP | Débit d'eau maximal | 3.8L/min |

| Pression de travail | 420Mpa | Pression de service continue | 320Mpa-380Mpa |

| Orifices d'entraînement Qté. | 1-2 | Température | 5-40°C |

| Type d'huile hydraulique | Huile anti-usure n°46 | Méthode de refroidissement | Échangeur de chaleur froide |

| Taille (L * l * h) | 1,7 m*1,1 m*1,4 m | Poids | 1T |

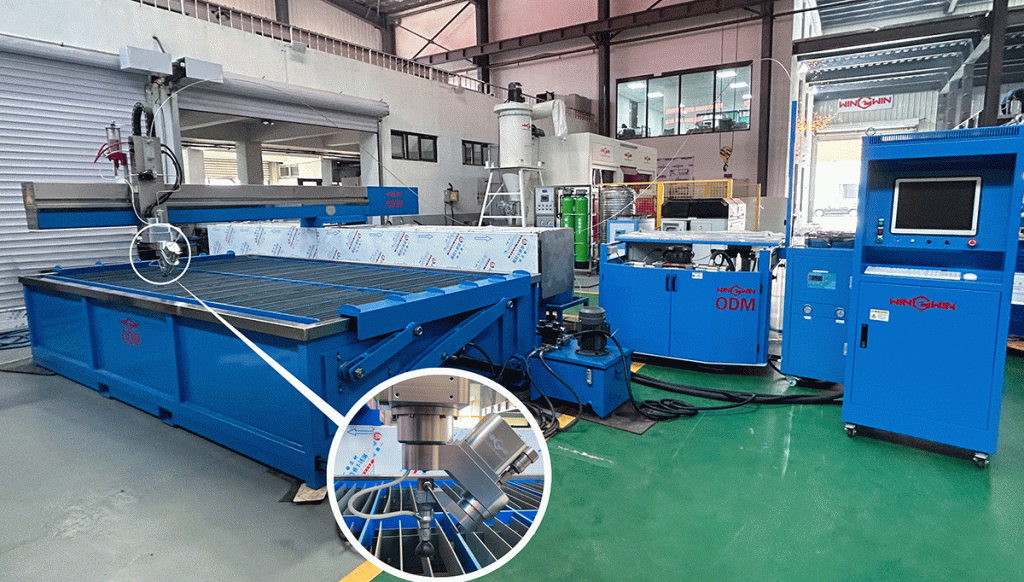

What are the characteristics of waterjet cutting machine:

It is widely used in the automotive interior water jet cutting industry. A WW40JET waterjet pump can drive 1-2 robot arms in the same time which is outstanding in production efficiency. With the design of dual intensifier,it can produce a flow rate of 3.8L/min.

- CNC control can cut various complex patterns

- A type of cold cutting that does not produce thermal stress, deformation or thermal effects.

- Environmentally friendly, safe and pollution-free, and will not produce toxic gases or dust;

- Can process various high-hardness and high-density materials, such as: glass, ceramics, alloy steel plates, stainless steel, leather, rubber, sponge, etc.

- It has a wide cutting range and is the only cutting method for composite panels.

- The cutting edge of the water jet cutting machine is smooth, without oxides, and rarely requires secondary processing. 7. Drilling, cutting, deburring and other tasks can be completed at one time;

7.Production costs are relatively low - High degree of automation Summary: Laser cutting has fast cutting speed and high cutting cost. It is a thermal cutting that requires material characteristics (heat-sensitive materials are not allowed), and there is light pollution and metal vapor pollution.

Waterjet cutting has no requirements on material properties and is pollution-free, and WINWIN’s metal cutting thickness can reach an astonishing 300mm. If you want to cut ultra-thick metal and a variety of materials, WINWIN’s waterjet cutting equipment is your best choice. choose.

If you wanna know more about WW 40 JET and watejet cutting machine,please feel free to contact me.