- Corte por jato de água WINWIN

- Máquinas de Jato de Água

- Produtos

- Sobre nós

- Notícias

- Contato

Português do Brasil

Português do Brasil

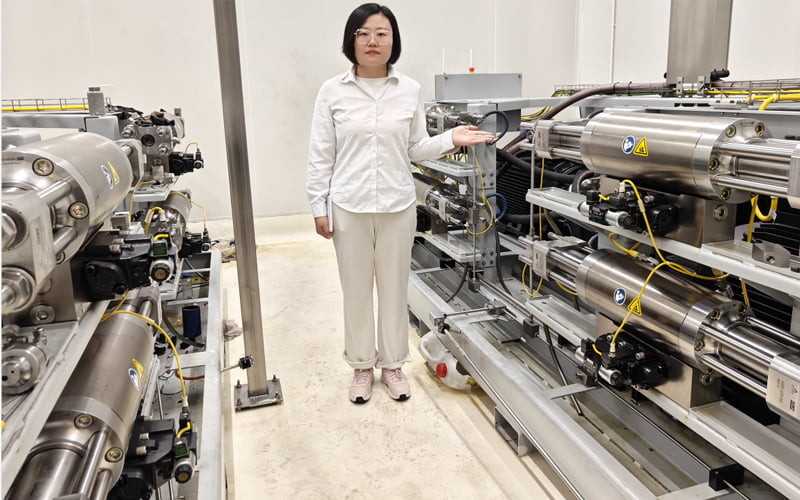

Emmy-Gerente de Vendas de Máquina Jato de Água

Gerente de Mercado do Sudeste AsiáticoAs a sales manager of waterjet machine, I am committed to providing innovative solutions to the marble industry

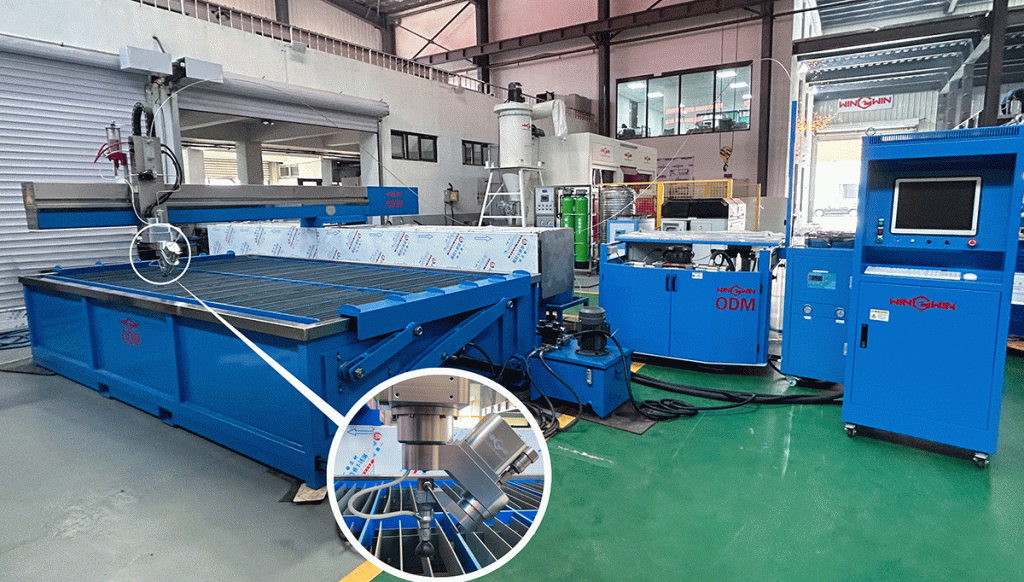

Our waterjet machine utilize a high-pressure stream of water and an abrasive mixture to achieve high-precision cutting and engraving on marble surfaces, revealing stunning details and intricate patterns.

Our waterjet machine offer several special advantages when cutting and engraving marble:

No heat impact: Compared with traditional thermal cutting technology, water cutting is a cold processing process and does not create heat-affected zones. This means there are no issues like thermal cracking, discoloration or deformation when cutting and carving marble.

Multi-material applicability: Our water cutting machine is not only suitable for marble, but also can handle various other types of materials, such as glass, metal, ceramics, etc.

Flexibility and creativity: Waterjet technology enables cutting and engraving of various shapes and designs, including curves, arcs, complex geometric shapes, etc.

Environmental protection and sustainability: Water cutting is an environmentally friendly processing method that does not produce harmful gases or waste materials, and the water can be recycled. Compared with traditional cutting methods, this reduces the impact on the environment and is in line with the concept of sustainable development.

Our goal is to provide customers with efficient, reliable and innovative solutions. We work closely with marble manufacturers, designers and construction companies to customize machines to their needs and provide training and technical support to ensure they can take full advantage of waterjet technology and create exceptional marble works