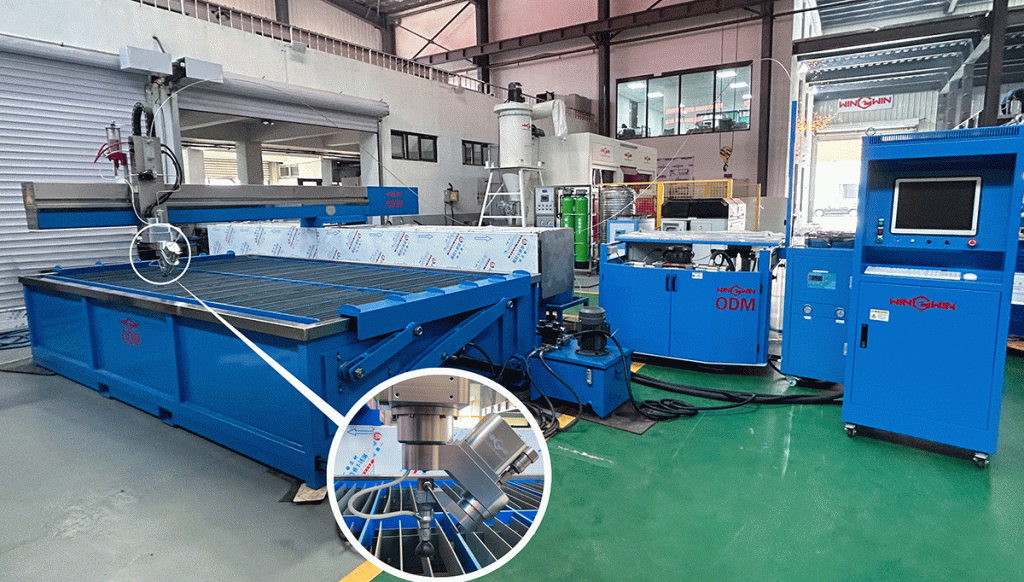

Роботизированная система гидроабразивной резки потолочного типа ABB 2400

The robot waterjet cutting system produced by WINWIN has been used for decades and is widely used in the automotive, aerospace, helmet cutting industries. Our customers in the United States and France who purchased this 2400 ceiling type robot cutting system is used for shape processing automation in the automotive industry upgrade.

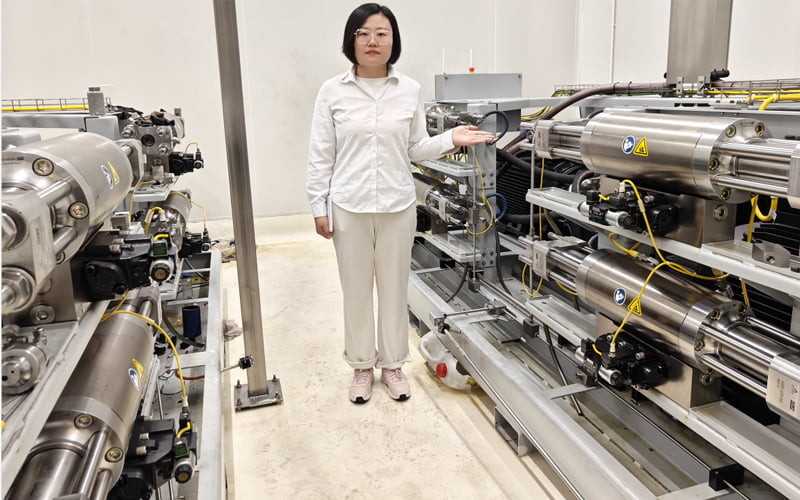

They were inspecting the robot waterjet cutting system produced in Winwin. Winwin’s robot waterjet cutting system can be flexibly equipped with ABB, FANUC, KUKA, and YASKAWA manipulators. Customized production is carried out according to customer needs, and the system is checked and accepted before delivery. Strictly control the quality.

1 | Марка робота-манипулятора: | ABB |

2 | Модель: | 2400 |

3 | Стиль: | Ceiling |

4 | Количество манипуляторов робота: | Triple |

5 | Приложение: | Резка салона автомобиля |

6 | Тип насоса: | SL VI 50 HP |

7 | Требуется оператор: | 2sets |

8 | Настроить доступно: | Да |

9 | В том числе устройства: | Рука робота, стол для резки, насос высокого давления, охладитель, система управления и т. д. |

WINWIN has long-term cooperation with many well-known automotive interior manufacturers in the world,BMW,TOYOTA,ANTOLIN,.etc.providing robotic waterjet cutting system to improve the production efficiency of the factory.

Water treatment will not affect the deformation of the rubber material in the interior. It is the first choice for many automotive interior manufacturers preferred.

This client company has factories in three countries, but there are many kinds of processing machines in their plant, so it is necessary to improve the space utilization rate.

The customer put forward the size requirements to us, and the overall robot working station length and width have precise requirements. , in view of the customer’s situation, we have designed the following two-layer robot waterjet cutting system for the customer

Камера гидроабразивной резки | Технология автоматизации процессов формы

At present, we have customized three sets of double-layer robot waterjet cutting working station for this customer and shipped them to three factories of their company.

The first set is to go to the customer’s site to install robotic equipment. In the past few years, we have flown to countries all over the world to install robotic cutting system and train thier staff.

The second set is to go to the customer’s factory for debugging.

The third set is that the whole set of robots is assembled and debugged in our factory and sent directly to the customer site

Now let’s take a look at this custom design together!

Configuration

1: Ceiling House Structure

2: Side-mounted triple ABB 2400 robot arms

3: Equipped with customized SL-VI 100HP intensifier pump

4: High-performance industrial chiller, the whole set of equipment can work well in hot areas

5: The powerful vacuum absorption system keeps the cutting parts firmly fixed on the cutting table

6: Система очистки воды, которая может продлить срок службы отверстия.

7: Система защиты для обнаружения персонала в рабочей зоне и защиты безопасности персонала.

8: Общая система управления

In this set of robot waterjet cutting system, we place the high pressure intensifier pump, chiller, vacuum adsorption system, water treatment system, and control system on the second floor for connection, which can save the use space of factory to the greatest extent and improve utilization efficiency.

Customers are also very satisfied with this custom design, and have successively purchased robotic cutting station of the same design from our company.

In the production of the intensifier pump, we customize it according to the customer’s needs. Our customer wants to work continuously for 24 hours.

Under such demand, we designed the SL-VI 50 HP double intensifier structure for the customer.Which can alternate 24 hours work, start without stopping.This pump also have a advantage of it can provide a maximum working pressure of 420 MPA, cutting ultra-thick materials is easy.

Бренд | ВИНВИН | Модель | SL-VI 50HP |

Имя | Water jet servo motor pump | Температура | 5-40°С |

Рабочее давление | 420 МПа | Режим вождения | Серводвигатель |

Material | Automotive Interior | Приложение | Система гидроабразивной резки |

Voltage | 380В | Номинальная мощность | 50HP |

Мощность аттенюатора | 2л | Постоянное рабочее давление | 320 МПа-380 МПа |

Максимальный расход воды | 3,8 л/мин | Количество отверстий | 3(0.17mm) |

Tank volume | 150L | Размер (Д * Ш * В) | 2,2м*1,4м*1,6м |

Масса | 1.5T |

|

|

Проснувшись однажды утром после беспокойного сна, Грегор Замза обнаружил, что он у себя в постели превратился в страшное насекомое.

How to choose a set of robot waterjet cutting system?

The common types of waterjet cutting machines in the industry are: robotic waterjet cutting system, abrasive waterjet cutting machines ,and portable waterjet .

Choose different models according to different working environments.Such as the demolition of outdoor oil tanks, the removal of ore in tunnel mining areas.

The abandoned cement columns on construction sites mixed with steel bars, etc., can be used for portable waterjet cutting.

Car carpets, complex 3D three-dimensional processing, car dashboards, and ship composite boards drilled ,can be used for robotic waterjet cutting machines.

Glass, metal, marble, ceramics, alloy steel, medical special materials, circuit boards, and temperature-sensitive materials can be cut with abrasive waterjet cutting machines

Why do many factories use robot waterjet cutting system to produce automotive interior parts?

Compared with general interior cutting machines, robotic waterjet cutting system are more environmentally friendly, efficient and accurate.

The robotic waterjet cutting system uses high-pressure water flow to cut materials ,which is without producing harmful gas and dust.

At the same time, the failure rate of robotic waterjet cutting workstations is relatively low, which can improve production efficiency and reduce production costs.

In terms of environmental protection, most of the current car roof interiors use a large amount of non-woven materials, but during the processing of this material.

A large amount of fiber dust will float in the air, affecting the working environment of employees, and even more If it cannot be controlled further, it will seriously affect the health of employees.

The processing quality and parameter consistency of the workpiece are also limited by the various anisotropy of the material.

The processing of automotive interior parts requires the design of special tools and molds according to the surface characteristics of the workpiece.

The design process is complicated and the price is high. Therefore, the production of automotive ceiling trim Technology urgently needs a breakthrough.

The robotic waterjet cutting technology can achieve precise cutting of irregularly shaped workpieces as long as the corresponding control program is adjusted.

The high automation and flexibility of robotic waterjet cutting is an inevitable trend in the processing of automotive interior parts.

The waterjet cutting intensifier pump and the waterjet cutting workstation of the ABB six-degree-of-freedom articulated robot have proved that the system has stable performance, good workpiece cutting quality, and high production efficiency, and is suitable for popularization and application.

Now we understand how to choose a suitable set of robotic waterjet cutting workstation.

If your factory also has materials that need to be cut and needs robotic waterjet cutting machine, please feel free to contact WINWIN waterjet.