Международная оборонная выставка IDEF в Турции

WINWIN Waterjet – The Defense Industry Cutting Solution

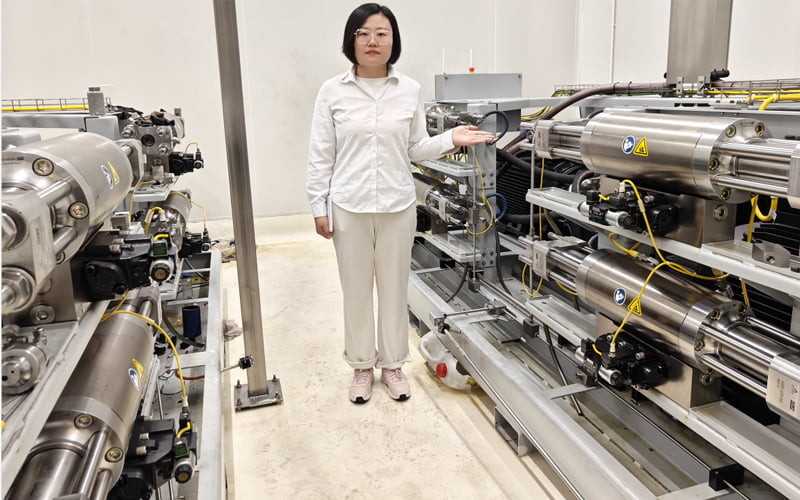

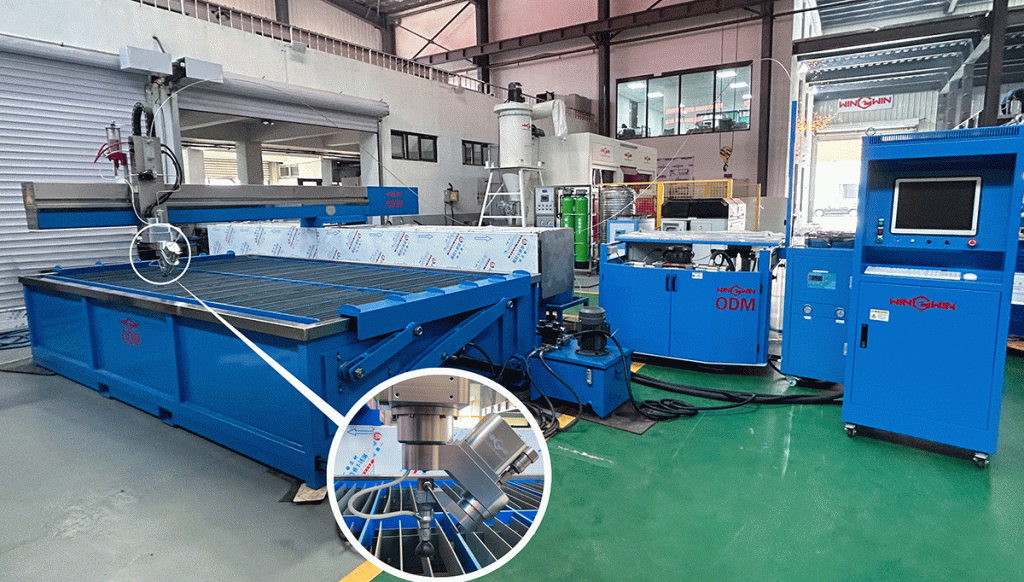

WINWIN intensifier pump technology and abrasive cutting heads have been extensively used in the defense industry.

it is widely used for cutting titanium, Inconel, brass, aluminum, and steel, as well as cutting composites from .039″ to 6″.

A complete waterjet table machine utilizing five-axis to a fully integrated six-axis motion control allows for precise metal cutting solutions for aircraft fuselages, tail and wing sections, rotary blades, and sheet-metal parts up to 12″ thick, depending on the material.

There are No Heat-Affected Zones (HAZ) and no burrs or rough edges (which eliminates the need for secondary finishing). This makes WINWIN’s waterjet products an ideal cutting solution for the aerospace and defense industry. There’s almost nothing that high pressure water and an abrasive waterjet additive cannot cut and cut well.

So when your margin for error is zero, trust WINWIN Waterjet and our global network of OEM experts who can customize a complete waterjet machine system to meet and exceed your needs.

Waterjet cutting technology has the following applications in bulletproof helmet cutting

Cutting ballistic materials: Ballistic helmets usually use high-hardness and high-strength materials, such as steel plates, composite materials, or ceramics.

Waterjet cutting technology can cut ballistic materials into the desired shape and size through the action of high-pressure water flow and an abrasive mixture without destroying the material’s anti-ballistic properties.

Making openings and grooves: Waterjet cutting technology can also be used to make openings and grooves in ballistic helmets. These openings and grooves can be used to mount accessories, vents or visual equipment to improve the functionality of the helmet.

Contouring: Waterjet technology can contour ballistic helmets to meet specific design requirements. By adjusting the cutting path and speed of the waterjet, precise trimming of the helmet’s shape can be achieved.

Repairs and Modifications: During actual use, ballistic helmets may become damaged or require modifications.

Waterjet technology can be used to repair damaged parts or make necessary modifications to the helmet to maintain its protective properties and adaptability.

It should be noted that when using water cutting technology to cut bulletproof helmets, relevant safety operating procedures should be followed to ensure the safety of the operator and the surrounding environment.

Additionally, since waterjet cutting produces splashes and shavings, proper safety measures need to be taken, such as wearing protective glasses and gloves.

Is waterjet technology suitable for cutting and repairing other protective equipment?

Yes, waterjet cutting technology is not only suitable for cutting and repairing bulletproof helmets, but can also be applied to cutting and repairing other protective equipment. Here are some other protective gear cutting and repair applications:

Body armor and stab-resistant clothing:

Waterjet technology can be used to cut and modify body armor and stab-resistant clothing to fit different body sizes and needs. It can also be used to repair damaged parts, such as replacing worn panels or reinforcing areas.

Chemical and fire-resistant clothing:

Chemical and fire-resistant clothing are usually made of multi-layer composite materials and have high protective properties. Waterjet technology can precisely cut these materials to create openings, reduce weight or trim unnecessary sections.

Specialty gloves and footwear:

Some specialty gloves and footwear incorporate complex material construction to provide protection and durability. Waterjet technology can help cut and repair these gloves and boots to suit individual needs or repair damaged parts.

Protective masks and goggles:

this technology can be used to cut the clear material of protective masks and goggles to create openings, adjust vision, or replace damaged parts.

What others applications in the defense field use waterjet cutting technology?

The following are some common application areas:

Cutting equipment and materials:

Waterjet cutting technology can be used to cut various defense equipment and materials. such as tank armor plates, aircraft structural parts, ship components, etc.

It can accurately cut different kinds of metals.

Like alloys and composite materials to meet the manufacturing, repair and modification needs of military equipment.

Demolition of Ordnance and Explosives:

In the military sector, there is a need to safely handle and dismantle unexploded ordnance and explosives.

Waterjet cutting technology can cut and dismantle these dangerous items .

the technology without causing an explosion, ensuring the safety of operators and the surrounding environment.

Chemical protection equipment processing:

Waterjet cutting technology can be used to process and dismantle chemical protective clothing, gas masks and other chemical protection equipment. It can cut and separate different parts for cleaning, repair and recycling.

Manufacturing military facilities and infrastructure.

Waterjet cutting technology is widely used in manufacturing military facilities and infrastructure, such as building structures, bridge components, fortifications, etc. It can cut a variety of materials, including concrete, steel and composite materials, to meet the needs of military engineering.

Repair and maintain equipment: Waterjet cutting technology plays an important role in repairing and repairing military equipment. It can be used to repair damaged armor, repair fighter shells, and replace damaged ship components.

What are the Applications of Waterjet Technology in the Defense Sector?

Waterjet technology helps in the manufacturing of a wide range of equipment for defense industry customers. Some of the areas and products that utilize waterjet cutting are:

Armour

Military Aircraft frames

Aircraft fuselages

Rotary blades

Frames and components for support vehicles

Jeeps

Weapon systems

Components for firearms such as the M16 and AR-15 rifles

Military humvees

Missile chassis and other components

Unmanned Aircraft Vehicles (UAV)

Unmanned AIrcraft Systems (UAS)

Shell Ejection Components

Bullet proof armour plates for vests and vehicles

Flexible feed chute assemblies for automatic ammunition systems

Structural components for many other defence equipment

High-wear defense applications