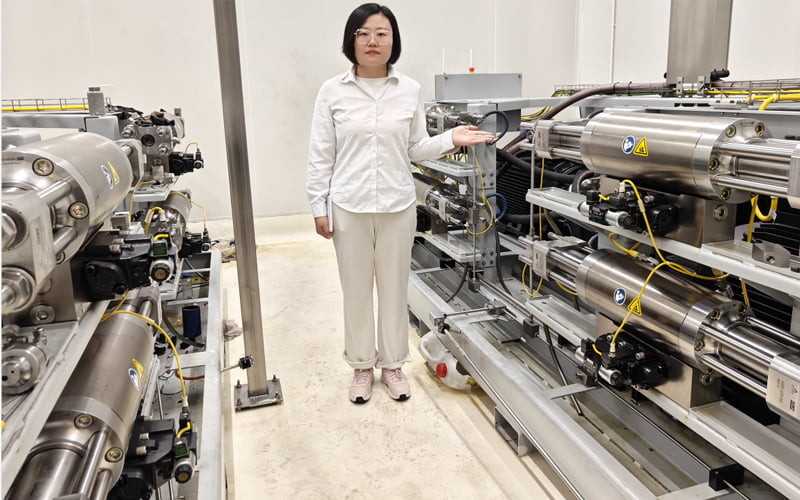

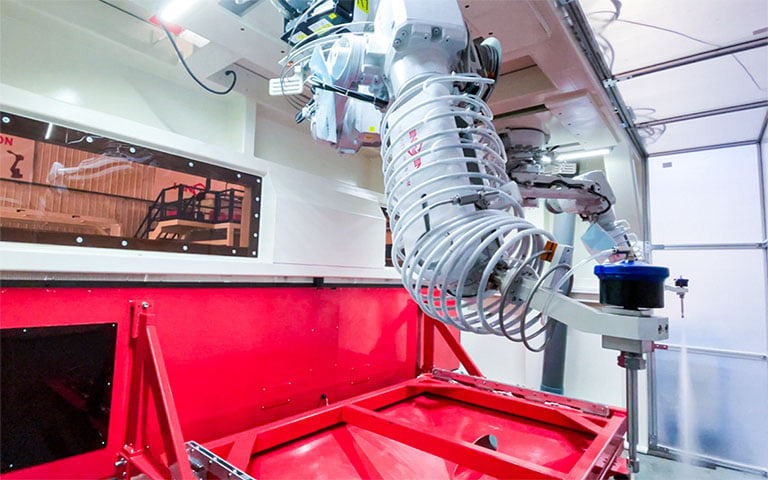

Роботизированная система гидроабразивной резки потолочного типа ABB-2600

Robot waterjet cutting is widely used in the following two main purpose.

The water is pressurized up to 60,000 bar using triplex plunger pump or with an intensifier pump. The robot guides the waterjet nozzle head along the target surface to process with efficiency. The waterjet kinetic energy is distributed with proper nozzle configurations allowing for fast, efficient and precise removals for various applications and part geometries.

Robot waterjet cutting, deburring, de-coring, and stripping all kinds of coating and contaminates from engine parts, car carriers (skids), molds, fixtures and tooling using pressurized water.

Камера гидроабразивной резки | Технология автоматизации процессов формы

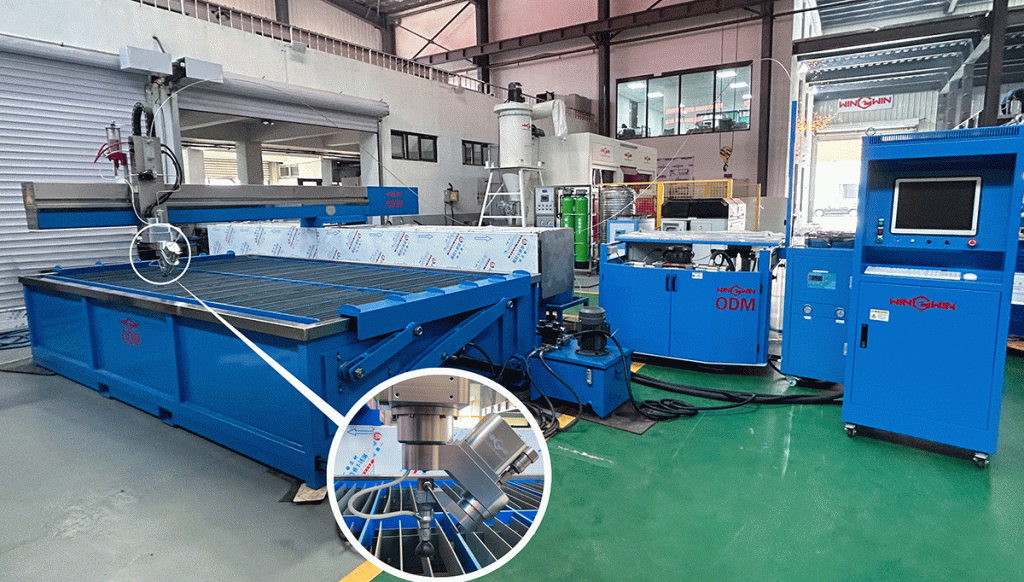

WINWIN provide the Automotive, Aerospace and Composite industries with cost effective robotic solutions. We have standard systems that can be equipped with up to (4) 6 axis. FANUC, ABB or KUKA,YASKAWA robots specializing in material removal applications such as:

– Waterjet Cutting (water only and abrasive added)

– Waterjet Surface Preparation & Cleaning

– Routing

– Knife and Ultrasonic Cutting

– Laser Cutting

| 1 | Марка робота-манипулятора: | ABB | |

| 2 | Модель: | 2600 | |

| 3 | Стиль: | Ceiling | |

| 4 | Количество манипуляторов робота: | Double | |

| 5 | Приложение: | Резка салона автомобиля | |

| 6 | Тип насоса: | Customized STREAMLINE SL-VI 50HP | |

| 7 | Требуется оператор: | 2 комплекта | |

| 8 | Настроить доступно: | Да | |

| 9 | В том числе устройства: | Рука робота, стол для резки, насос высокого давления, охладитель, система управления и т. д. | |

This Robot waterjet cutting solution is a ceiling type.Double robot arms structure.Equipped with a rotating table.Which is also the most commonly used structure in combination. It performs well in terms of efficiency, failure rate, safety, operation, etc.

This solution is basically suitable for cutting interior parts of all small cars to design a new robot waterjet cutting workstation solution and provide corresponding equipment to replace the existing old waterjet cutting cell in the customer’s factory to improve the processing efficiency of automotive interior carpets. , reduce maintenance costs.

The following are core configuration the advantages of this robotic water cutting structure:

Configuration of Robot Waterjet Cutting

Pressure: 360MPa-420MPa

Features: Each robot integration is equipped with a rotating table, and a new robot integration system can be added at any time. The floor space is relatively small, and the hanging manipulator cuts efficiently.

1: Rotary Working Station

2: ABB 2600 robot arm

3: Equipped with SL-VI 50 HP intensifier pump

4: Industrial chiller

5: Vacuum adsorption system

6: Water purification system

7: Safety protection system

8: Общая система управления

Advantages

Advantages of Robot Waterjet Cutting

- The closed shell structure can better prevent dust, noise and water mist generated during processing.Avoid damage to personnel and on-site equipment caused by cutting head accidents.Comprehensively protecting and improving the working environment.

- Consistent with the customer’s existing water injection workstation structure.It is convenient for the operator to quickly understand.And also familiar operating modes reduce the time required for installation and training.

- The customer’s factory already has a set of robot waterjet cutting workstation. WINWIN has carried out the same frame and structure design.Which is conducive to dimensional measurement and layout planning.

- At present, the ceiling dual robot arms is the best solution for handling and cutting car carpets.

It can fully meet the requirements of the cutting range, improve processing efficiency and ensure production time. - The robot waterjet cutting system, high-pressure intensifier pump, universal control system, water softening system, cooling system, vacuum adsorption system and safety guard are all standardized equipment to ensure quality and simplify after-sales service.

Advantages of Waterjet Pump

1. SL-VI 50HP pump has a double intensfier structure, which can be replaced for 24h operation without shutdown to ensure production efficiency

2. 60, ooopsi ultra high pressure, ensuring production efficiency

3. 3.8L/min water flow, which can drive 1-3 robots at the same time

4. Servo motor can save 30% cost

5. The intensfieri pump spare parts are universal

| Бренд | ВИНВИН | Модель | SL-VI 50HP |

| Name | Water jet servo motor pump | Температура | 5-40°С |

| Рабочее давление | 420 МПа | Режим вождения | Серводвигатель |

| Material | Material | Приложение | Система гидроабразивной резки |

| Напряжение | 380В | Номинальная мощность | 50HP |

| Мощность аттенюатора | 1л | Постоянное рабочее давление | 320 МПа-380 МПа |

| Максимальный расход воды | 3,8 л/мин | Количество отверстий | 3(0.17mm) |

| Tank volume | 150L | Размер (Д * Ш * В) | 2,2м*1,4м*1,6м |

| Масса | 1.5T |

The above is a complete set of robot waterjet cutting system. The usual industry is used to cut automotive interior materials.

In addition to customized Robot waterjet cutting.We also provide customers with industrial robots.

In the field of industrial robots, there are four major families: ABB, KUKA, FANUC, and YASKAWA. WINWIN waterjet is one of the designated agents of the four major robots.

With a total market share of more than 75%. The movement speed is fast.The trajectory is accurate.

the rigidity is good, the flexibility is high, and the stability is strong, which can shorten the processing time, speed up the production efficiency and reduce the labor cost.

So what is automotive interior?

Types of automotive interiors mainly include the following:

Seat belts, carpets, ceilings, steering wheels, seats, airbags.door panels, interior lighting, pillar panels, instrument panels, trunks (trunks).interior acoustic systems, air circulation systems, engine compartment interiors file system, etc.

Industrial robots also play an important role in automobile production, especially with the rapid development of the automobile industry.

Industrial robots can act autonomously and are widely used in different production links.Such as arc welding, spot welding, assembly, handling, painting.testing, palletizing , Grinding and polishing and other complex operations.

So a lot of robots are needed to complete the manufacture of a car. Industrial robots have become the key intelligent equipment in car production.

WINWIN can not only provide you with robot waterjet cutting projects and robot arms.But also this year we flew to countries all over the world to provide technical support and training for our customers.

Providing our customers with high-quality machines, mature technical support, timely and effective after-sales service.

Each machine has its own characteristics, if you also want professional and effective support from WINWIN, feel free to contact us!